In between Utah lift visits last week, I ventured to Tooele, a sleepy town west of Salt Lake to see America’s newest lift factory. Skytrac Lifts opened its 25-acre campus last summer, which will supply chairlifts and surface lifts to customers throughout the US. During my visit, the Skytrac team was finishing getting settled while gearing up to build at least nine new lifts this summer.

Skytrac has grown substantially since building its first drive terminal at Monarch Mountain, Colorado in 2010. With the late Jan Leonard as one of the founders, the company quickly found a niche providing ski areas high quality yet uncomplicated fixed grip chairlifts. As of this winter, Skytrac has built 82 lifts in three countries along with numerous retrofits, modifications and relocations.

Leitner-Poma of America acquired Skytrac in 2016. The two companies remain distinct brands under Italian conglomerate High Technology Industries (HTI). Skytrac and Leitner-Poma often bid separately on the same projects and retain unique product lines. While both subsidiaries make fixed grip chairlifts, Skytrac recently took over the surface lift (T-Bar and Platter) side of the business while Leitner-Poma focuses on larger chairlifts and gondolas. For a surface lift, Skytrac manufactures operator houses, towers and control systems but imports carriers and terminals from Leitner’s specialized facility in Slovakia. Skytrac’s original products, the Monarch fixed grip chairlift and Hilltrac inclined elevator, are produced almost entirely in Tooele.

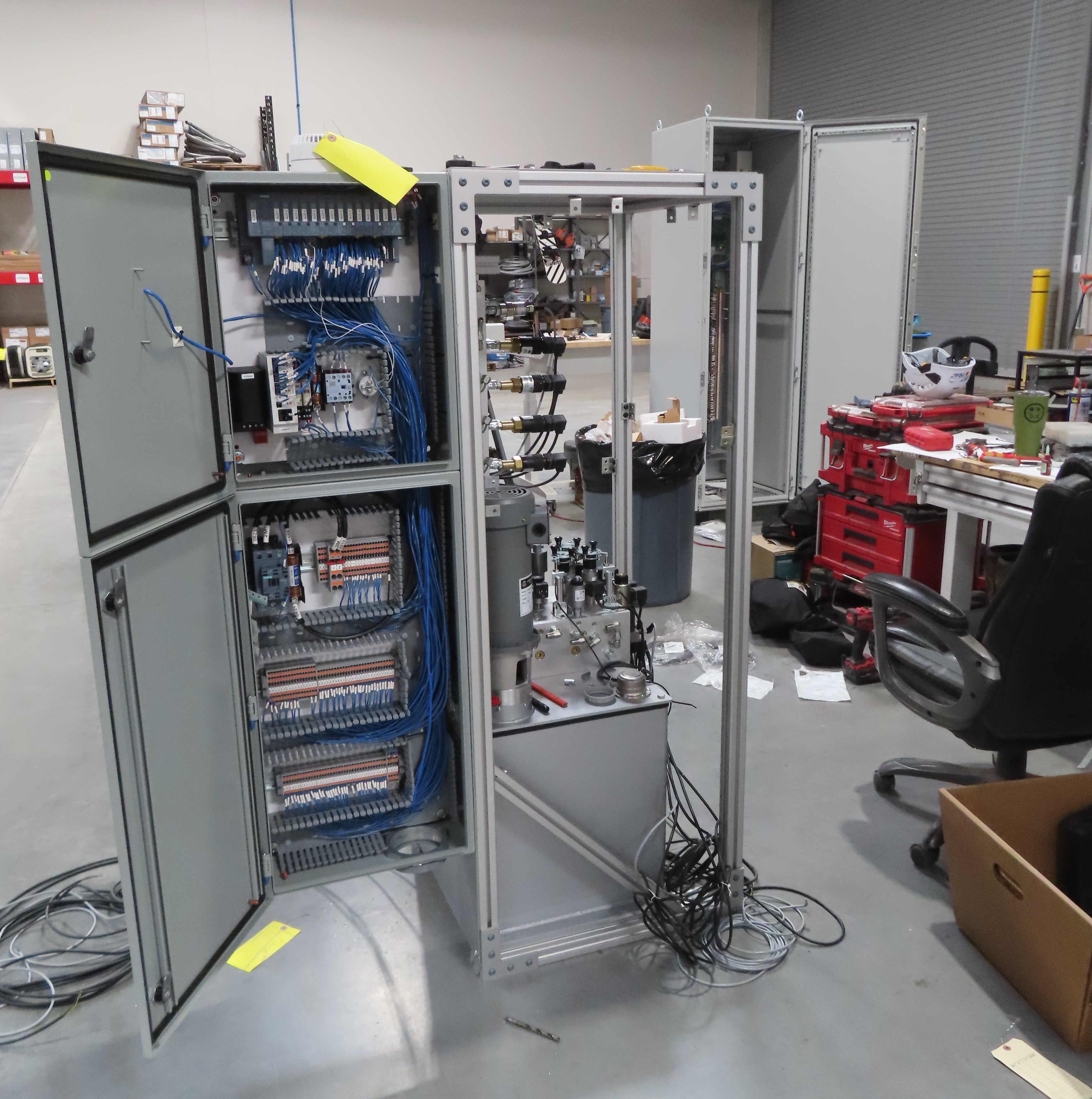

HTI’s 130,000 square foot building replaced a smaller site Skytrac leased site near the Salt Lake City airport. Tooele lies roughly 30 minutes west with ample land and two nearby technical colleges. With Skytrac occupying 90,000 square feet, the $27 million facility can produce nearly an entire chairlift under one roof. Everything from chairs and towers to bullwheels and control systems are made here. Electrical, engineering and sales departments work right alongside the production hall. Skytrac lifts are truly made in America with typically only the haul rope and gearbox imported from abroad.

The new facility is even larger than LPOA’s Grand Junction plant with ample room for growth. Bobby Langlands, Skytrac’s Sales Engineer and my tour guide, said the factory could probably pump out 20-plus lifts a year, up from the eight to ten they generally do now. In addition to production, there’s a cavernous parts warehouse, which will expand to include stock for the growing number of Leitner-Poma lifts in the Intermountain region. HTI sister companies Prinoth and Demaclenko also have space for parts and service in Tooele.

One of the coolest things when touring a lift factory is seeing parts tagged with names of mountains they’re headed to. Lift manufacturers generally produce components in order of contract signing and I saw pieces destined for Pats Peak, Ski Butternut, Monarch and Snowmass. Skytrac produces the most common components in advance based on a forecast. As an example, the company is producing 120 tower crossarms this spring and will do a second production run later if orders warrant. One thing that makes a Skytrac lift relatively affordable is the number of parts that are common among every lift. The chair bail, for example, is the same regardless of whether a customer orders a double, triple or quad.

Skytrac utilizes several robotic welding machines in Tooele along with automated plasma cutters. Hard working people do the rest of the work by hand. The new facility includes a state-of-the art sandblasting and paint booths for finishing operator houses and motor room enclosures. Galvanizing is completed offsite by contractors.

In addition to Skytrac, Leitner-Poma, Demaclenko and Prinoth, a fifth HTI company is also involved with the Tooele project. Wind energy manufacturer Leitwind supplied a 250 kilowatt wind turbine capable of powering the entire plant. Italians were on site last week testing the turbine to prepare to hook up to Rocky Mountain Power’s regional grid.

Skytrac built nine complete lifts in 2024 and plans to do at least that many again this year. During my visit, the construction team was outside preparing to fan out across the country as Skytrac nears its 100th new lift.

Very nice article, Peter. Thank you for sharing. Skytrac is quickly growing and I wish them well. It will be interesting to see how Doppie ups their game to be more competitive.

LikeLike

Is that why the drive terminal is called Monarch? Because the first one was built at Monarch Mountain?

LikeLiked by 1 person

Yes.

LikeLike

I think it also worked well as a name on its own, the “king” lift. Probably wouldn’t have stuck with the “Schweitzer” or the “Lost Trail” terminal if one of those mountains were their first.

They definitely couldn’t call it the “Nubs Nob”

LikeLike

Peter, do you remember which of the lift components in the pictures (aside from the tagged control stand) are headed to Pats? Thanks

-liftnerd

LikeLike

Thanks Peter for the tour of the facility, and thanks HTI/Skytrac for giving you permission to share it with us. It is really neat to see the birthplaces of lifts, and all the effort that goes in to the build, that often gets taken for granted as they whisk us up our favourite mountains.

LikeLiked by 4 people

I remember in one of your earlier posts about a Skytrac, mentioning how it was confusing why they went with the Euro style chair vs a standard North American bail. Part similarity certainly makes sense, everything is better at scale! Plus, on the only true Skytrac I’ve been on, the liftie wasn’t bumping the chairs so it’s really not a huge deal!

LikeLiked by 1 person

The control panel with the six buttons and the phone on the side is heading to Snowmass Cirque lift.

LikeLike

https://liftblog.com/2025/03/24/inside-skytracs-new-home-base/#jp-carousel-123636

LikeLike

Can anyone explain to me the difference between a funicular and an inclined elevator?

LikeLike

Both are cable railway systems that ride on tracks and service steep terrain.

A funicular has 2 carriers (cabins) that are attached to each other via the haul rope and pass each other at the midpoint of the track. The descending carrier acts as a counterweight for the ascending carrier.

An inclined elevator has only one carrier and a straight track with no passing zone in the middle. The haul rope is attached to the uphill and downhill sides of the carrier and it has a separate counterweight system that often operates in conjunction with the drive mechanism.

Hope this helps.

LikeLiked by 2 people

The hilltrac is not rope propelled like most inclined elevators but more like a battery powered cog railway. In operation a hilltrac is fully automatic like an elevator and will garage at a designated landing usually in a building out of the weather and come to whichever landing it is called to. Since a hilltrac operates closest to an inclined elevator it is marked as such otherwise Michael has the definition.

LikeLike

Thanks. I always wonder why funiculars and inclined elevators aren’t featured on this blog.

LikeLike

Super interesting!!! What a great article, Peter! Nice to see that the work of the team is getting out there –– that Skytrac team does some really exciting work! Growing up close the the industry, it is amazing to see and hear about the pre-sale, build, and marketing that goes into a project from pre and post production!

LikeLiked by 1 person