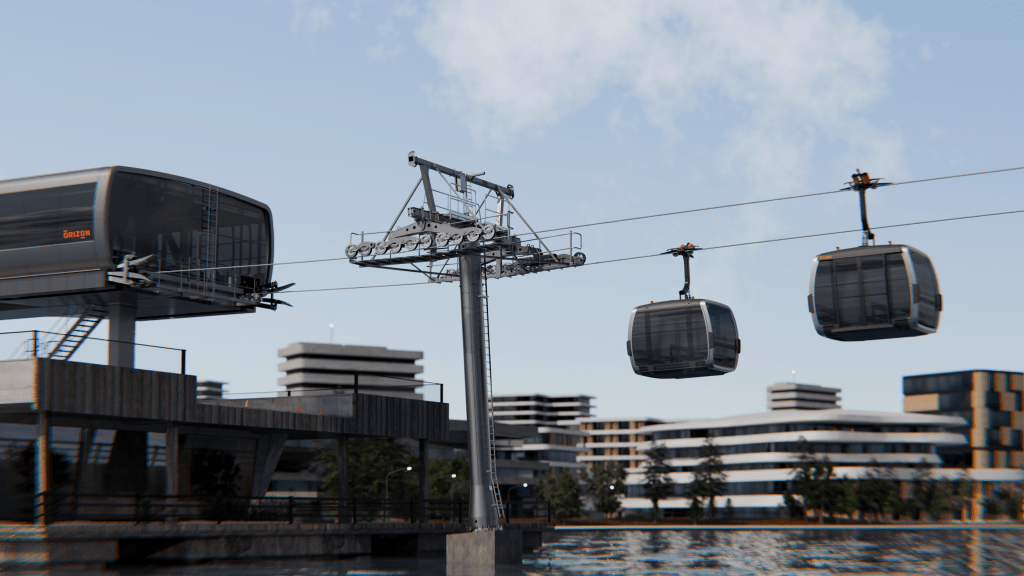

After years of dabbling in the detachable space, MND today unveiled its full range of next generation detachable lifts at Mountain Planet in Grenoble. The French firm known for its avalanche control and snowmaking products has invested more than €20 million developing the Orizon line, which includes both detachable chairlifts and gondolas. Orizon will offer all the premium features customers may want in a detachable lift including direct drives, bubbles, and modern gondola cabins seating 10, 16 or 20 passengers. More than 60 people worked on the development of Orizon and approximately 100 more will join MND in the coming year to support the new product line.

“With this innovating range of detachable, single-cable gondola lifts and chairlifts, MND is consolidating its position as a global player and aims to win new market share in a fast-growing sector,” the company noted in a press release. “The Orizon range equipment caters to the most demanding configurations: steep gradients, long distances, large vehicles and high flow rates.”

This is not the first time MND has dipped its toes in the detachable space dominated by Austria’s Doppelmayr and Italy’s HTI Group, owner of Leitner and Poma. In 2017, MND completed its first detachable lift at La Plagne, France. The Envers chairlift suffered problems from day one and was never duplicated but gave the company valuable experience to learn from. Later, MND pivoted to partner with Bartholet of Switzerland for detachable technology, building lifts around the world including at Waterville Valley, New Hampshire. That partnership proved successful but ended last year when HTI acquired a majority stake in Bartholet. With MND coming back to the market with its own product, three large European conglomerates will offer detachable lifts on a global scale.

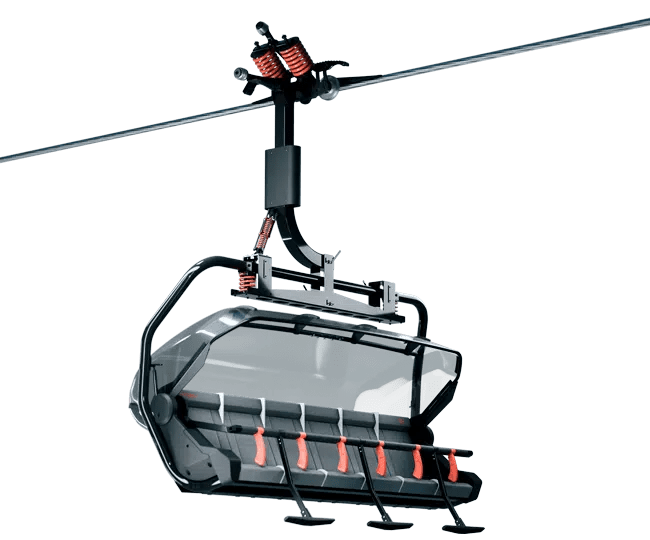

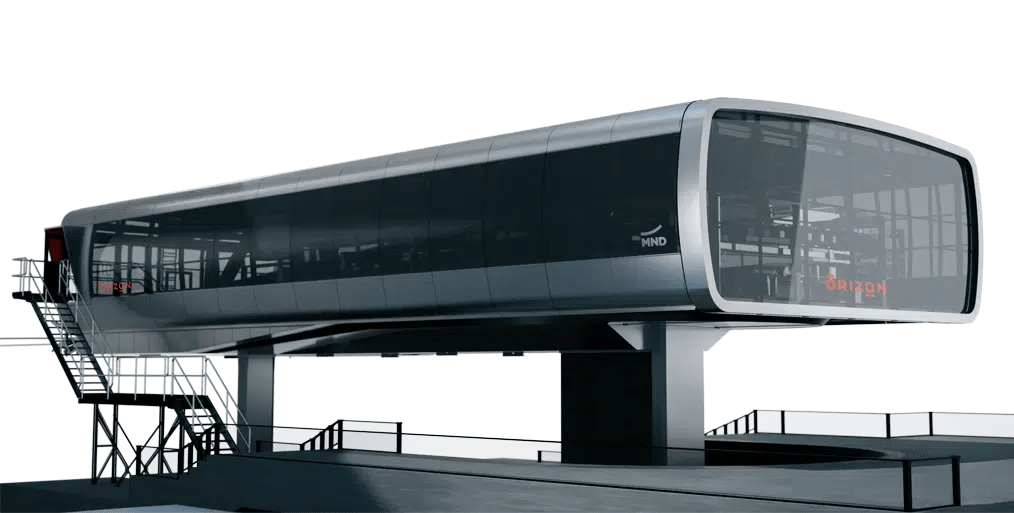

MND’s chairs, gondolas and stations were crafted in partnership with the Stellantis Design Group. Americans know Stellantis for its car brands – Chrysler, Dodge, Jeep and Ram – but the company’s design arm also partners to develop products for other applications. The MND Orizon range is decidedly modern and designed to fit in both alpine and urban spaces. Orizon lifts will be geared toward demanding applications, capable of seven meters per second and up to 8,000 passengers per hour per direction. Two grips, P10 and P20, can accommodate up to 66 millimeter haul ropes.

The Orizon line will be produced in a new €10 million plant in Sainte-Hélène-du-Lac, France. MND did not reveal when or where the first Orizon lift may launch.

While it’s not as pretty as the D-line, really like the design. I think we need some more diversity in the US lift market. I hope that some company will develop a cheaper detachable model in the US that could use smaller terminals like the tube ones on some uni-g mid stations or even the Yan ones(without the problems). I also hope Leitner-Poma will bring their own premium version to the US. The funny thing about being a lift nerd is that usually it’s more exciting to ponder the future than the present new lifts.

Sorry about the unorganized rant. I got a little bit lost in thought. ;)

LikeLiked by 1 person

I couldn’t agree more. I understand why Leitner Poma sells a more budget-friendly detachable product in the LPA terminal than their more premium offerings in Europe such as the Poma Multix and the Leitner Pininferina, but I don’t see why LP doesn’t offer either of these products as a premium upgrade or as their 8 pack product offering and import them from Europe considering Doppelmayr already offers D-Lines that are shipped over from Europe while also offering the more cost-effective Uni-G

LikeLike

I feel like it may take a little while for this product to make its way into North America but I definitely could see the first few Orizon detachables launching at ski resorts in Europe.

LikeLike

Good to see a new line from MND after Bartholet pulled out the rug from under them. It will be a tough go to start, they may have to discount lifts to little or no profit to have resorts take the risk and to have some proven operating lifts to show future buyers (the Yan detach saga will still be in the minds of resorts). I wish them success, as having options other than Doppy or HTI will help keep lift (and therefore ticket) prices from ballooning in the future.

LikeLike

Waterville isn’t in the market at the moment, but I wonder if they still would want to use MND? The next chair in their masterplan is a fixed grip quad to replace Sunnyside.

LikeLike

I must say these look very good, hopefully we could start seeing them around in the near future.

Are those MND designed and built cabins? Would that be a first for them?

And, the grips, are those also in-house design?

And finally, given this is a North America-centered blog, what are MND’s operations in North America like? and what would is the likelyhood of these showing up in the US or Canada in the forseeable future?

LikeLike

I was wondering the same thing on grips, it seems to be original. Looks like after a decades of different grip designs, Poma, Doppelmayr and MND all came to a simlar design: action arm and springs are together, pivot around the grip point.

LikeLike

I gonna be completely honest, MND’s cabin design is not necessarily the most creative, their cabin design looks a lot like Leitner’s luxury symphony cabin.

MND Orizon Cabin:

Leitner Symphony Cabin:

LikeLiked by 1 person

Are 16 and 20 passenger cabins on a monocable lift new? I’m not familiar with anything like that presently offered. Seems like a gamechanger for signature lifts with high capacity needs, but I wonder: with the cabins taking up more space, fewer of them can be in a station at a time. Can total capacity really be much higher than a 10 passenger with the cabins nearly bumping against one another in the stations?

LikeLike

The MND 20 passenger cabins on a monocable are to compete with Doppelmayr’s new TRI Line with 20 person Stella cabins. The TRI Line system is basically a DLine station that’s slightly modified to be a 3S with 20 person cabins. They can move up to 8000PPH so it seems MND is interested in competing in this mass people mover space.

LikeLike

From Reomntées Mécaniques’ page for gondolas of more than 10 people, which obviously isn’t a complete list but is very extensive, it appears that there are some 16 person monocables out there. The three RM have all are from 1995-2000, and have Sigma Espace 16 cabins, though the lifts themselves are of different manufacturers. The construction dates might imply that this type did go out of fashion for some reason, though I wouldn’t be sure.

20 person monocables I don’t think exist anywhere right now, though I could be wrong.

LikeLike

“Can total capacity really be much higher than a 10 passenger with the cabins nearly bumping against one another in the stations?”

The short answer is depends on carrier size and station length, the long answer below:

The limiting factor for Gondola terminals is not so much the cabin size but the speed it has to go in the turnaround to avoid bumping into other cabins. Historically this wasn’t an issue because Gondolas could only carry so many people and the interval between cabins was wide enough so that the gondola in front already rounded the corner before the next one would be close enough to bump it.

The gondola at Aspen Mountain is a good example here, notice how much space there is between cabins in the turnaround, so it can move slowly and people have plenty of time to get in and out of the cabins. https://skiliftblog.files.wordpress.com/2017/02/img_7920.jpg . BUT, it can only move 2000 people.

With higher capacity, the less time between cabins becomes a problem, you can stack as many cabins as you want in the straight sections, but if they crawl along at the same speed in the turnaround they’ll get nicked by the one behind it. The first minute of this video at Winter Park (https://www.youtube.com/watch?v=UTCYT7T6xnk) shows how the cabins really hustle around the turn but slow down again in the straight section(s) on both sides.

If you want plenty of time to load at a slow speed (a necessity for high-capacity systems), you want a longer station so you can unload on one side and load on the other, so the turnaround is just there to get the cabins out of the way of the next one.

The steamboat gondola, for example, has super-long terminals to accommodate half a dozen cabins in the straightaways at the same time, which gives plenty of space and time for people to load the cabins instead of running around the turnaround to catch the cabin. https://skiliftblog.files.wordpress.com/2021/12/img_3003.jpg

For cabins larger than 8/10 passengers, the issue of cabins stacking up is mitigated because

1 – Bigger cabins usually mean more time between them, this beefy 3S gondola in Austria moves 3900 people/hour, but with 32-person cabins that’s 30 seconds time between each one, an eternity in lift world. The longer interval also allows the cabin to slowly crawl along the turn without the next cabin creeping up on it, which is really important if you’re trying to load and unload dozens of passengers at once.

https://www.remontees-mecaniques.net/bdd/reportage-3s-penkenbahn-doppelmayr-6361.html

2 – Bigger cabins require a wider line gauge, so the turnaround isn’t as tight of a radius compared to a 8 or 10 passenger gondola. A more gradual turnaround means that there can be less time between cabins without risking them colliding with one another, and the cabins don’t have to hustle around the turn. The village gondola at Mammoth, which is an older 15-pax design, is a good example of this. https://skiliftblog.files.wordpress.com/2017/04/img_2580.jpg

I suspect that 3S and 20-person cabins of the future will reach a point where the cabin frequency is so high that the turnaround cannot accommodate loading/unloading anymore just to get out of the way fast enough, straight loading will become the norm when you’re trying to move that many people.

LikeLike

You’re absolutely right and I’d want to add to this.

The highest capacity 10-MGD Gondolas in Europe already have straight only loading, the greatest example being the Gigijochbahn in Sölden which carried 4500p/h. The mountain station even has a special layout to allow a longer unloading section so it does not have to be as long as the valley station. I think the cabins are already almost as close together as possible, perhaps 4800p/h might be achieved in the future but that’s already pushing it unless the loading speed is increased.

https://www.youtube.com/watch?v=BaVcmKD1fQ0

The real solution is not necessarily larger cabins in general, but wider cabins. There is no real benefit in having cabins longer parallel to the lift line, as the cabins will take longer to pass one another when loading, keeping capacity effectively the same (unless you introduce standees to an otherwise shorter sitting only gondola). Therefore, wider cabins are needed, because each length of cabin has more capacity. Shorter, wide cabins are most economical because you do not need as tall hangers as seen in 3S systems, reducing build cost.

Doppelmayr and MND here have used this principles to create their 20-MGD and Tri-Line systems capable of 8000p/h. If higher capacity is needed in the future, I can see a further increase in width of the cabins and more standing room.

LikeLike