- Epic Pass adds one more Austrian partner – the mighty Sölden.

- Kirsten Lynch resigns as CEO of Vail Resorts and is succeeded by former CEO Rob Katz.

- Vail details the next phase of its Resource Efficiency Transformation Plan, including reorganizing resort divisions, combining snowmaking/grooming/terrain parks into one department and restructuring summer operations.

- President Trump delays implementation of a new 50 percent tariff on the European Union to July 9th.

- The 10 percent “Liberation Day” tariffs are briefly struck down then reimposed by different federal judges.

- Entabeni Systems closes on its purchase of Black Mountain, New Hampshire.

- Holiday Mountain, New York looks to fund a new chairlift in part by making the top station a billboard along NY-17/future Interstate 86.

- A guest gets caught hanging from clothing on a Mammoth chairlift over Memorial Day Weekend.

- Bartholet releases its 2025 Reference Book.

- A new chairlift project pops up in the Forest Service NEPA system for Aspen Mountain.

- No one bids on privatizing Marble Mountain; the Government of Newfoundland and Labrador will continue operations.

- A new aerial tramway in Texas gets $7 million closer to construction.

- Deer Valley won’t break ground on Snow Park Redevelopment this summer after all.

Month: May 2025

Quebec’s First Skytrac Coming to Mont Sutton

Mont Sutton plans to revitalize its teaching side of the mountain in 2026 with a fixed grip quad from Skytrac. The new lift will replace three aging Mueller doubles and become the first Skytrac in Quebec. The news marks a significant milestone as Doppelmayr dominates the Quebec market and its 75 ski areas (more mountains than any other Canadian province or US state.) Skytrac’s expansion into Canada has been measured thus far with the first Monarch in Canada debuting in 2018 and three projects following at Searchmont, Ontario in 2020, 2021 and 2022. The Leitner-Poma subsidiary has yet to build any lifts in Western Canada.

Sutton’s new lift will load near the main chalet and transport 2,400 skiers per hour. It will feature a loading conveyor and greatly improve the learning experience for beginners and intermediates. As part of the project, Mont Sutton will move an existing conveyor lift, add a second conveyor, implement RFID gates and improve snowmaking around the new chair. The CA$8 million lift project, funded in part by the Government of Quebec, represents the largest investment in the resort’s 65 year history. “This announcement is the culmination of the planning work of all the teams over the past few years,” noted Jean-Michel Ryan, President and CEO of Mont Sutton. “The Skytrac quadruple chairlift, thanks to the quality of the overall proposal made by Poma Canada, meets all the essential criteria sought by Mont Sutton.” Construction is expected to commence in spring 2026 and be complete in time for the 2026-27 ski season.

Instagram Tuesday: Alyeska

Every Tuesday, I feature my favorite Instagram photos from around the lift world.

Doppelmayr to Grow Canadian Headquarters

Doppelmayr Canada will dramatically expand its base in Saint-Jérôme, Quebec, situated between Montreal and the Laurentian Mountains. The new facility will feature approximately 120,000 square feet of indoor production, service and warehouse space; 31,000 square feet of covered outdoor space; and a 34,000 square foot office and training facility. The news comes just a few weeks after Doppelmayr broke ground on a similar expansion in Salt Lake City. “The new facility will be a state-of-the art manufacturing facility where we will continue to design and produce the highest quality ropeway systems in North America,” noted Luc Guy, CEO of Doppelmayr Canada. “We are excited to expand our production capabilities and our workforce and continue Doppelmayr’s legacy of building ropeways in Saint-Jérôme.”

The existing Saint-Jérôme plant opened in 1978 and today specializes in building UNI-G detachable equipment for Canada and the United States. The new headquarters will rise alongside the existing building and allow Doppelmayr to better serve the growing North American market. “Our employees do an outstanding job completing all our ropeways on time and to the highest standards,” said Gerhard Gassner, Doppelmayr Group Managing Director. “However, due to growing market volume, the new building has become essential to continue meeting these expectations,” he continued. The United States and Canada comprised 29 percent of the Group’s revenue last year, eclipsing €300 million.

Canada Economic Development for Quebec Regions (CED) granted Doppelmayr Canada a repayable financial contribution of $3 million for the project. Construction is anticipated to start at the end of May with production set to begin at the new facility by the fourth quarter of 2026.

News Roundup: Austrian Giants

- Austria’s Saalbach, Zell am See-Kaprun, Mayrhofen, Hintertux and Silvretta Montafon join the Epic Pass as partner resorts, bringing Epic to nine European destinations.

- Poma releases its 2024 Reference Book highlighting projects around the world.

- Eaglecrest may not meet a 2028 deadline to complete its used pulse gondola.

- America’s only summer only ski area will open this year for the first time in three.

- Whaleback meets a $250,000 fundraising goal for lift repairs.

- Opposition organizes against proposed Grand Targhee expansion.

- Bluewood, Washington to sell chairs if its new lift project is on track by September 1st.

- Hawaii’s first gondola is proposed on the North Shore of Oahu.

- A gondola is floated for Ft. Lauderdale, Florida.

- Also Anaheim, California.

- Marmot Basin’s visitation drops 30 percent due to last year’s fire in Jasper.

- Silver Mountain delays summer opening due to gondola repairs.

- Timberline Helicopters, the company that installs the majority of lift towers in the West, breaks ground on a $13 million expansion in North Idaho.

- The nonprofit organization that’s been trying to revive Cuchara, Colorado inks a 40 year operating lease for the mountain.

- Vail Mountain intends to begin work on the lift projects I wrote about last week next summer, subject to Forest Service approval.

- President Trump proposes a 50 percent tariff on imports from the European Union starting June 1st.

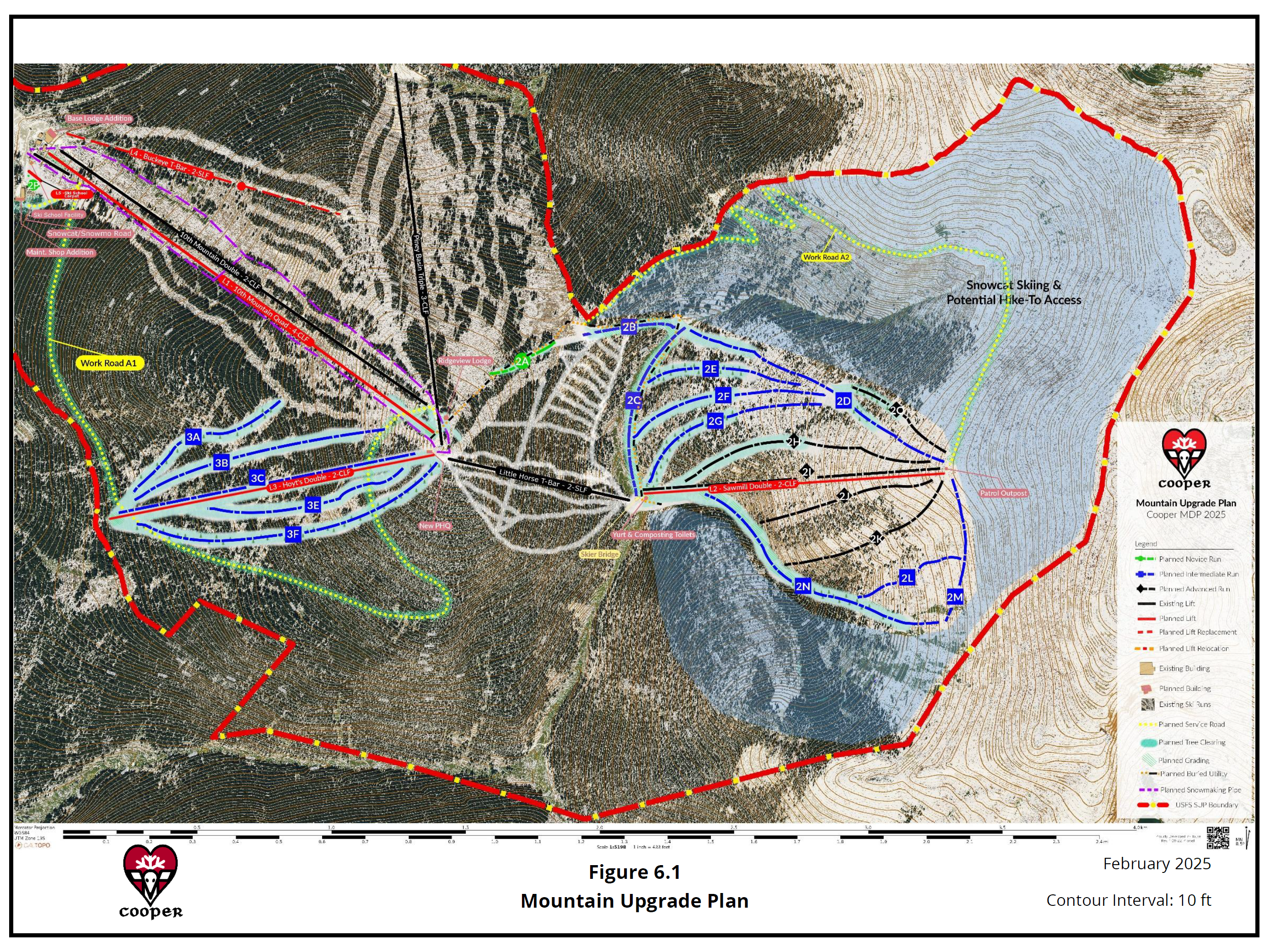

Cooper Master Plan Prescribes Four New Lifts

Colorado gem Ski Cooper is thriving among giants. Over the past ten seasons, visits have grown 63 percent, fueled in part by affordable lift tickets. Last winter, a midweek ticket cost $45, regardless of the time or method of purchase. Peak days cost $110 with Fridays and Sundays running a bit less. Surrounded by Copper Mountain, Vail, Breckenridge and Beaver Creek; Cooper’s customer base naturally skews local. But the hill also attracts a growing number of skiers from the Front Range and surrounding states, owing to its accessible tickets and laid back character.

Cooper is an outlier, especially in Colorado. Lake County owns the fixed assets like buildings and the hill straddles two National Forests. Operations are handled by Cooper Hill Ski Area Inc., a 501(c)4 nonprofit organization. Last year the mountain brought in $6.8 million in revenue, more than triple its sales in 2011. Expenses have also creeped up but not as quickly as revenue. The ski area netted $1.1 million in 2024 and carries no debt. This model has allowed consistent re-investment including a new conveyor lift in 2006, the Little Horse T-Bar expansion in 2019 and overhaul of the Piney Basin triple in 2021. Future improvements will be funded by retained earnings, not debt or taxpayer funds.

Because Cooper sits on Forest Service land, it’s required to periodically file a Master Development Plan (MDP.) The current master plan dates back to 1999 and Cooper is in the final stages of perfecting its 2025 Master Development Plan. The ski area expects to submit the plan to the Forest Service in July for acceptance. Like with all MDPs, projects are conceptual in nature and subject to NEPA approval before implementation. Unlike most master plans, Cooper’s 2025 MDP includes projected costs and phasing. In true Cooper fashion, it was prepared in house rather than by a consulting firm.

Phase one includes relief for the base-to-summit 10th Mountain Double. Replacement of the workhorse 10th has long been envisioned and was first approved in 2000. Instead of replacement, Cooper now plans to run a new fixed grip quad alongside the double and utilize both on peak days. The new quad combined with water/sewer upgrades, a lodge addition and parking expansion in phase one would cost $13 million.

Phase two would see a new lift constructed on Chicago Ridge called Sawmill. This double chair would serve 250 acres within Cooper’s existing permit area but never previously lift-served. Sawmill would rise 1,093 vertical feet and increase Cooper’s overall vertical drop by 382 feet. “A future Master Plan may envision further lift served use of the Chicago Ridge area within the SUP,” the plan notes. New double chairs are exceedingly rare in the United States with the last one installed at Arapahoe Basin in 2020. The last instance before that was six years earlier at Crystal Mountain, Washington. Like with those examples, a double would allow Cooper to service intermediate and expert terrain with a relatively fast lift (550 ft/min) at relatively low cost. Expansion up Chicago Ridge would also require a new patrol facility, skier bridge and trail improvements. Together with a second beginner conveyor in the base area, phase two totals $12 million.

Phase three includes Cooper’s first-ever snowmaking system and a second new double chair called Hoyt’s. This lift would service 60 acres of intermediate-pitched meadows on the west-southwest face of Cooper Hill. Hoyt’s double would span approximately 4,000 feet with a vertical of 942 feet and five new trails.

A third project in phase three is a replacement for the Buckeye Platter, which dates back to 1983. This project is planned as a T-Bar, increasing capacity by 120 percent. The mountain’s second T-Bar could run at a speedy 600 feet per minute with an intermediate unload station. Combined with a new lodge and additional parking, phase three is estimated to cost $14.5 million.

Cooper’s current comfortable carrying capacity (CCC) totals 1,819 guests but gets exceeded several times most winters. If all MDP projects are completed, the ski area could comfortably accommodate 3,682 guests, effectively doubling capacity. “Ski Cooper’s goals are to continue operating at less than full capacity, but add lifts, lift capacity, and terrain in order to improve circulation, keep wait times at lifts at a comfortable level, improve overall terrain offerings, and therefore maintain the reliably high-level ski experience Ski Cooper’s guests have come to expect,” the plan notes.

Lake County is currently soliciting feedback on the plan before submittal to the feds.

Instagram Tuesday: Silver Queen

Every Tuesday, I feature my favorite Instagram photos from around the lift world.

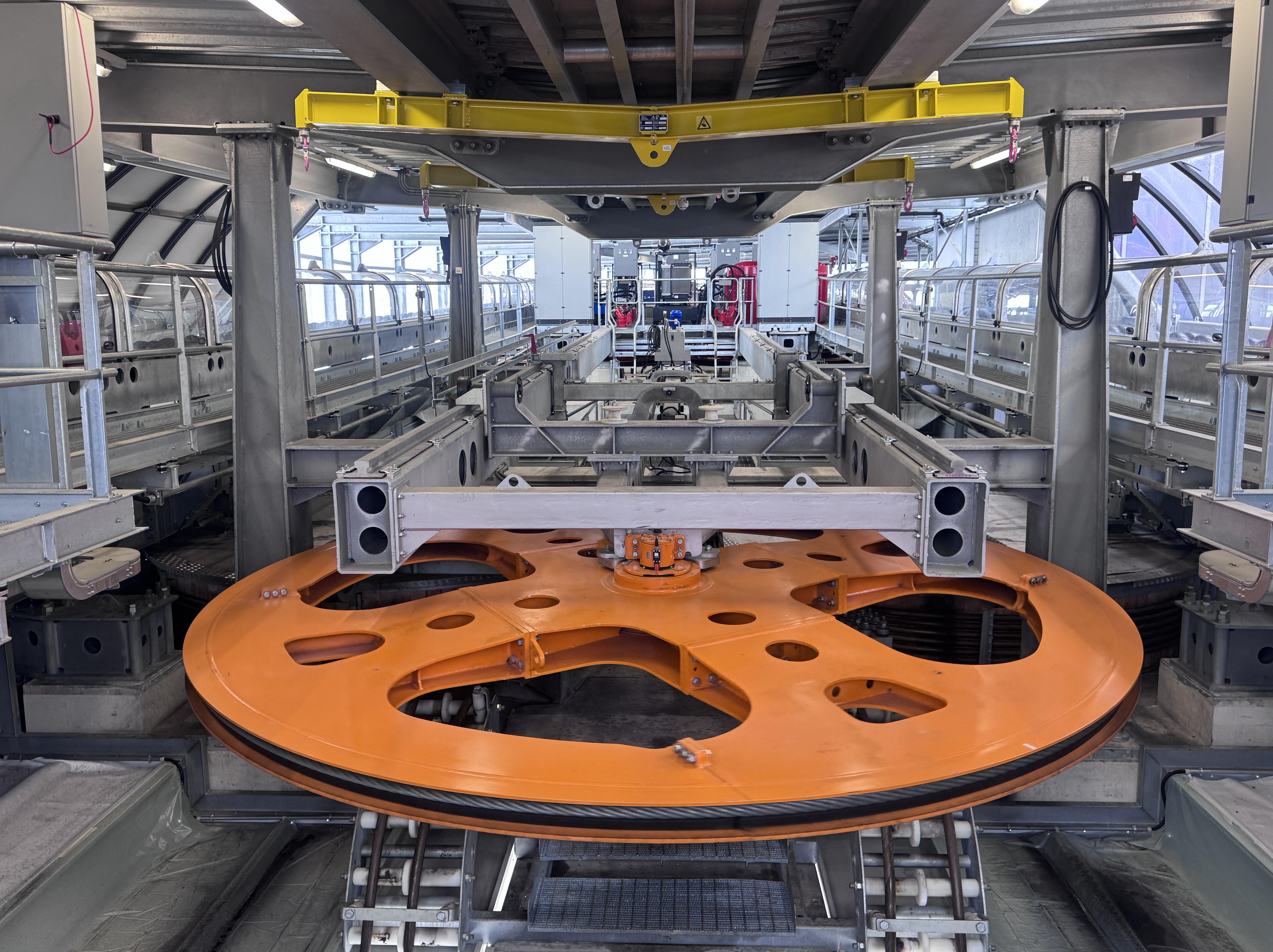

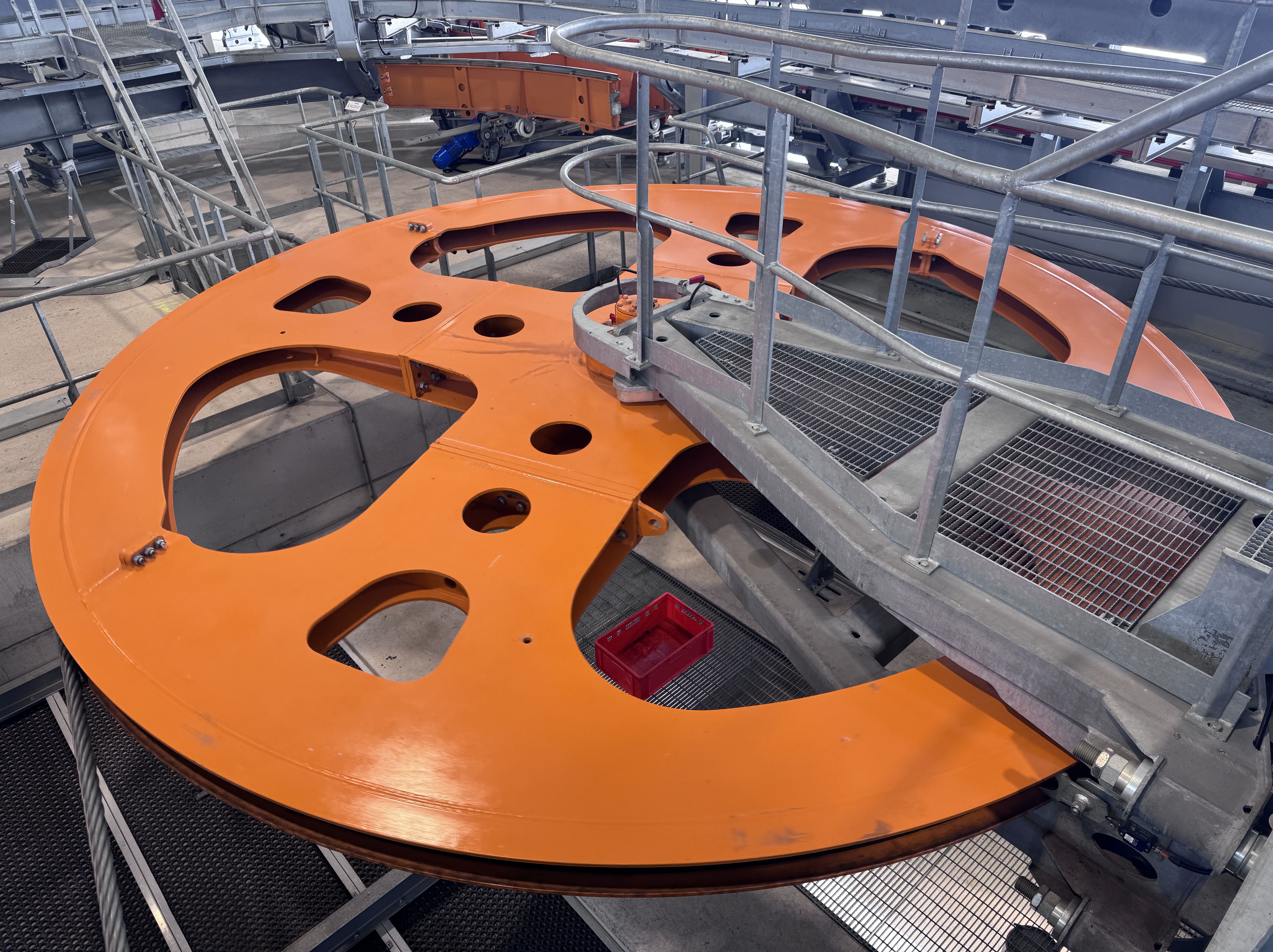

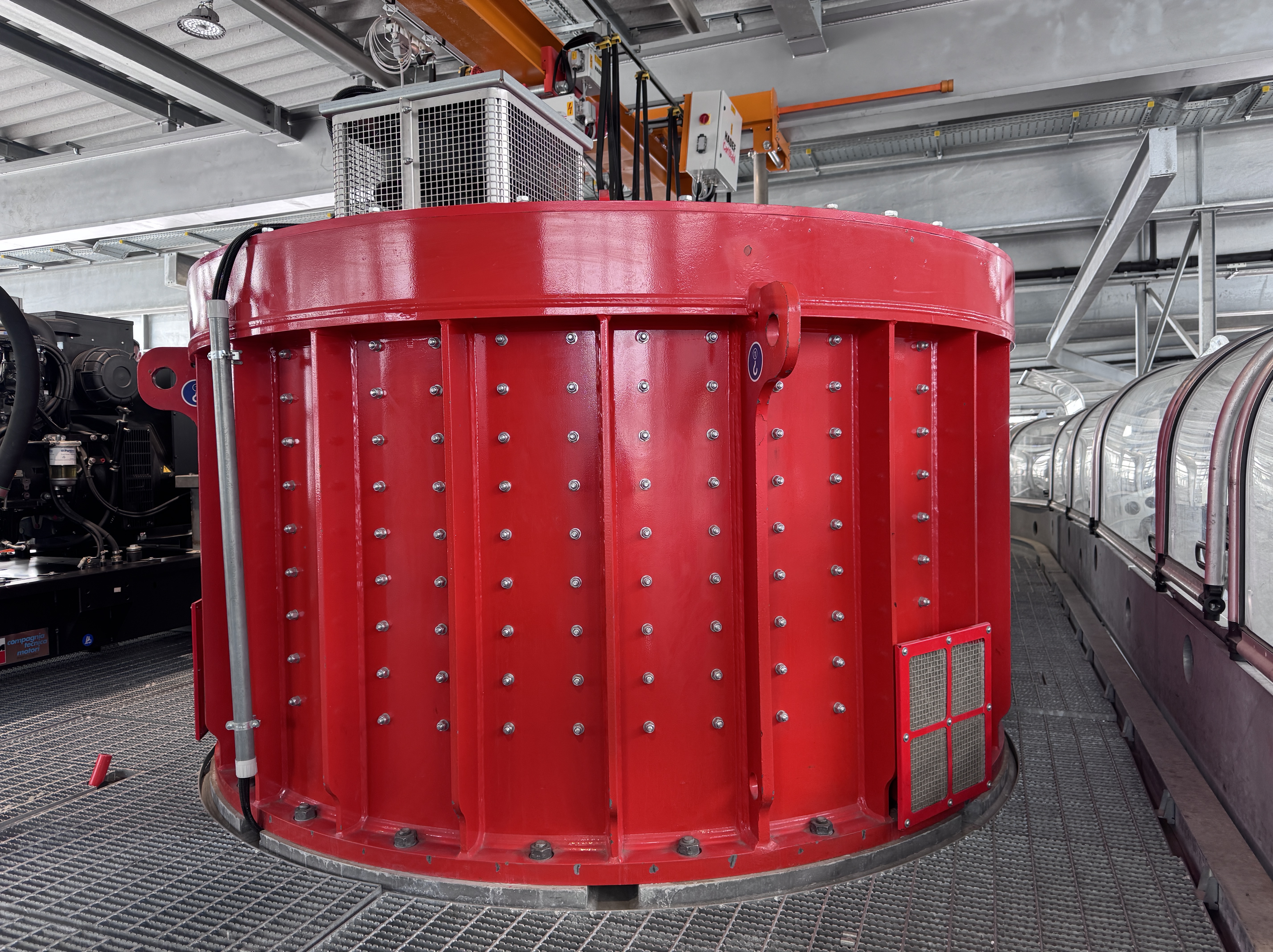

An Adventure in Europe with Leitner-Poma

A few weeks ago I ventured to the Alps with a delegation from Leitner-Poma of America. LPOA is the North American arm of High Technology Industries, the holding company behind iconic European ropeway builders Leitner, Poma and Bartholet. While Leitner-Poma of America fabricates upwards of 85 percent of its equipment in Colorado and Utah, the US outpost partners closely with its sister companies back in Europe. The trip included peers from a dozen US and Canadian resorts along with Leitner-Poma employees and partners (full disclosure, LPOA covered the cost of my trip other than airfare.)

Our first stop after arriving in Munich was the Nebelhorn, near the town of Oberstdorf. Leitner constructed a state-of-the-art 2S system here in 2021, replacing several jig-back tramways. A 2S combines the efficiency of a monocable gondola with the stability and long spans of a tram. The Nebelhornbahn features two sections, automated parking and striking Symphony cabins designed by Pininfarina. Oberstdorf Lifts CEO Henrik Volpert took us on a fantastic tour of the gondola’s motor rooms, maintenance bays and parking areas. Not only does Henrik oversee seven ski areas in the region but he also serves as President of the German Ski Areas Association.

At the top of the 2S, we continued onto an older jigback tramway, the first of several on this trip. It was closing day for this resort and locals were still skiing on the upper mountain while we ate lunch.

After lunch we headed to the other side of the valley, where another of Henrik’s mountains had already opened for summer. This family ski area features a mountain coaster, several kid-friendly activities and hiking in the summer season (there’s no real offseason here.) We rode a neat monocable gondola with a 90 degree angle station to mid-mountain. Everything on the lift was top of the line including Leitner’s premium stations, a direct drive and Diamond EVO cabins.

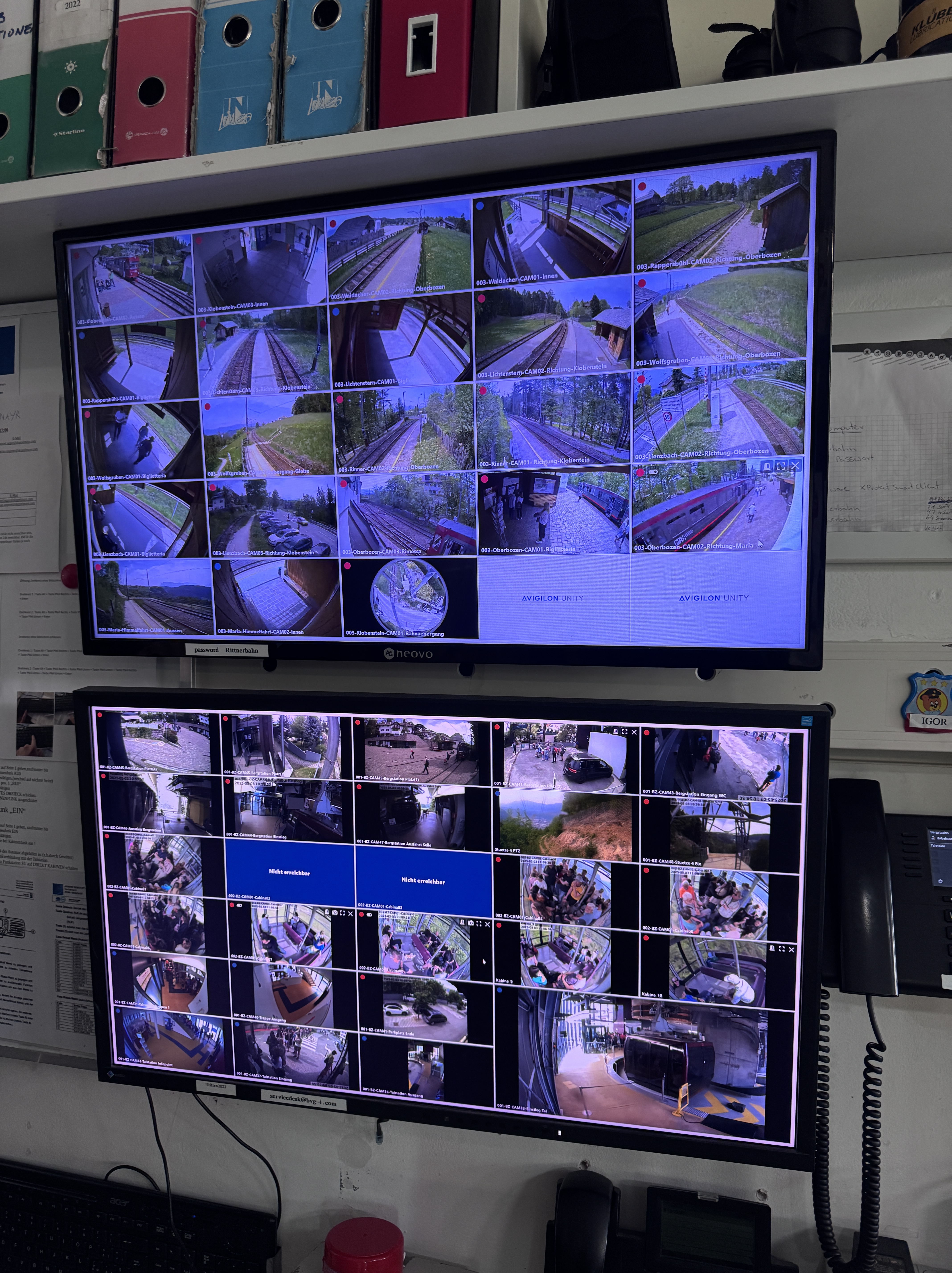

The next day took us through Austria to Italy, where Leitner’s first 3S system operates between the city of Bolzano and the mountain village of Ritten/Renon (towns in this region carry both German and Italian names.) This unique 3S operates in a pulse fashion with cabins coming to complete stops in the stations while the line keeps moving at varying speeds. The 3S serves as public transit for more than a million riders a year and costs just five Euros to ride. The lift spans nearly 15,000 feet with ten 35 passenger cabins. At the top, an electric train carries riders further up the plateau with views of the Dolomites.

A highlight of the trip was seeing Leitner’s factories, the largest of which lies in the company’s hometown of Sterzing. There’s a ski area right in town, of course, but it had closed for the season. Our host here was Anton Seeber, the friendly leader of HTI Group and its many brands. Sterzing is a true production facility with workers and machines cutting and welding raw steel into bullwheels, tire banks and towers. Sterzing also produces casings for direct drives used all over the world. We visited this factory on a Sunday so no one was working but it was cool to see components in varying stages of completion.

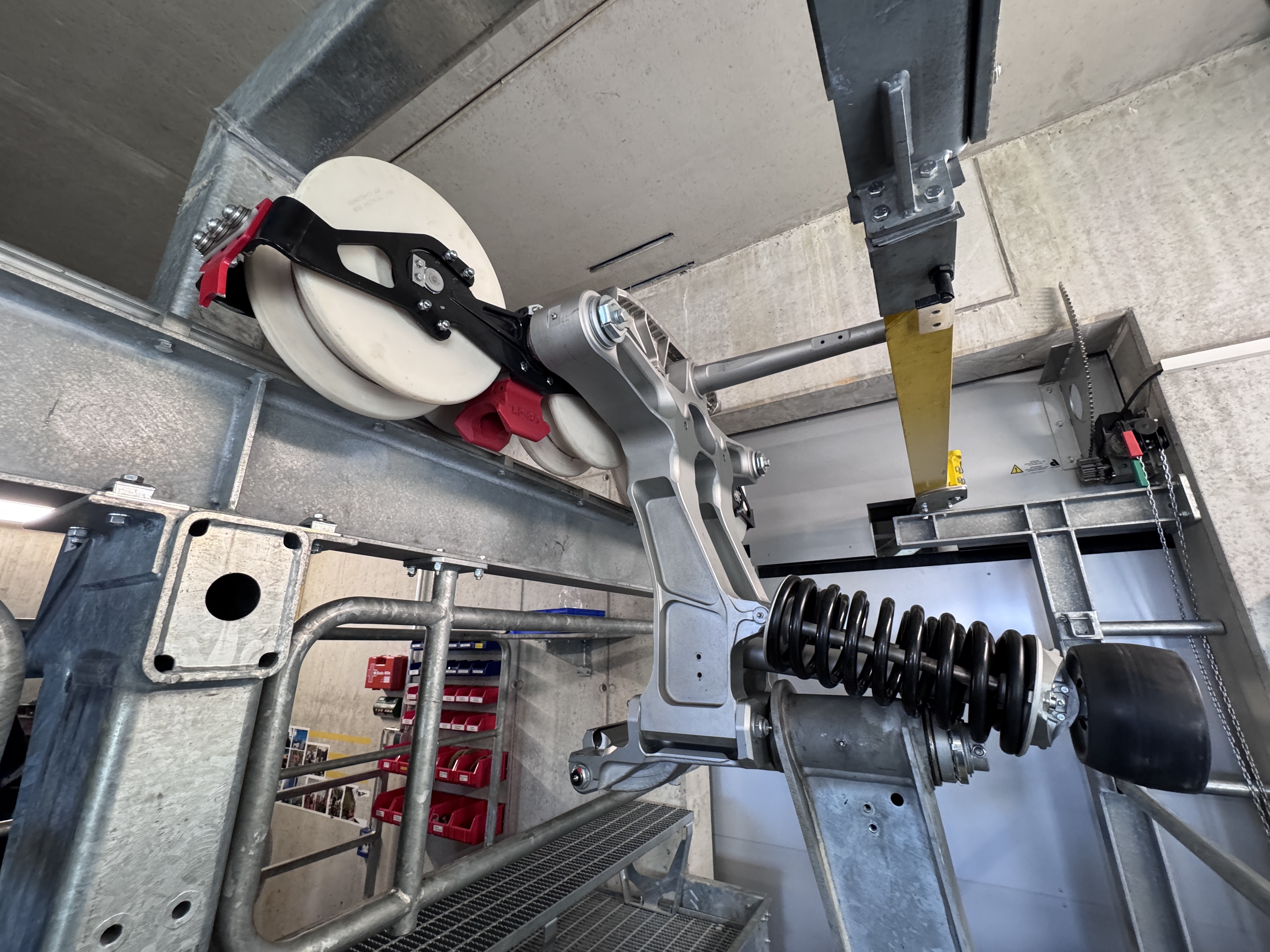

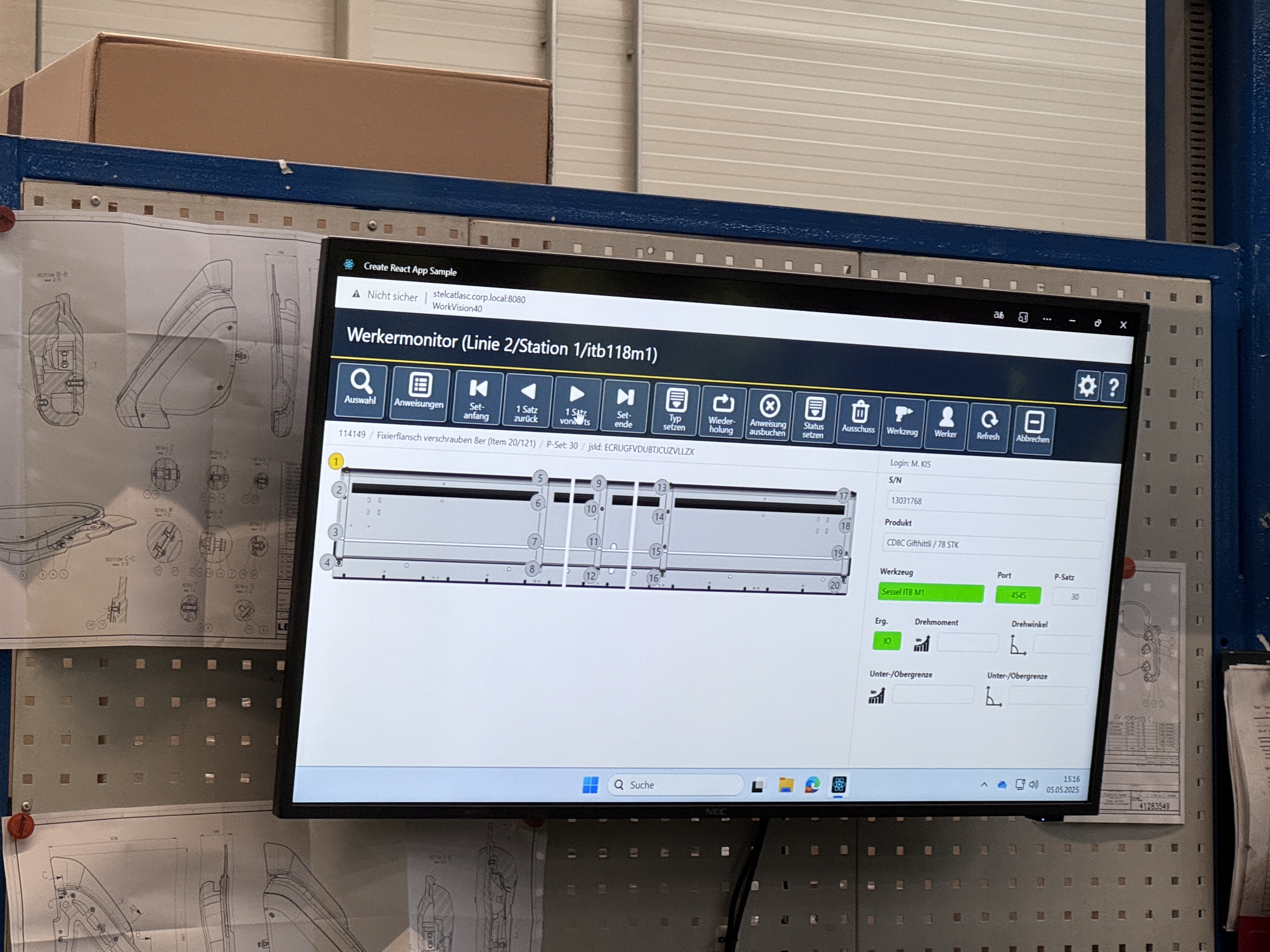

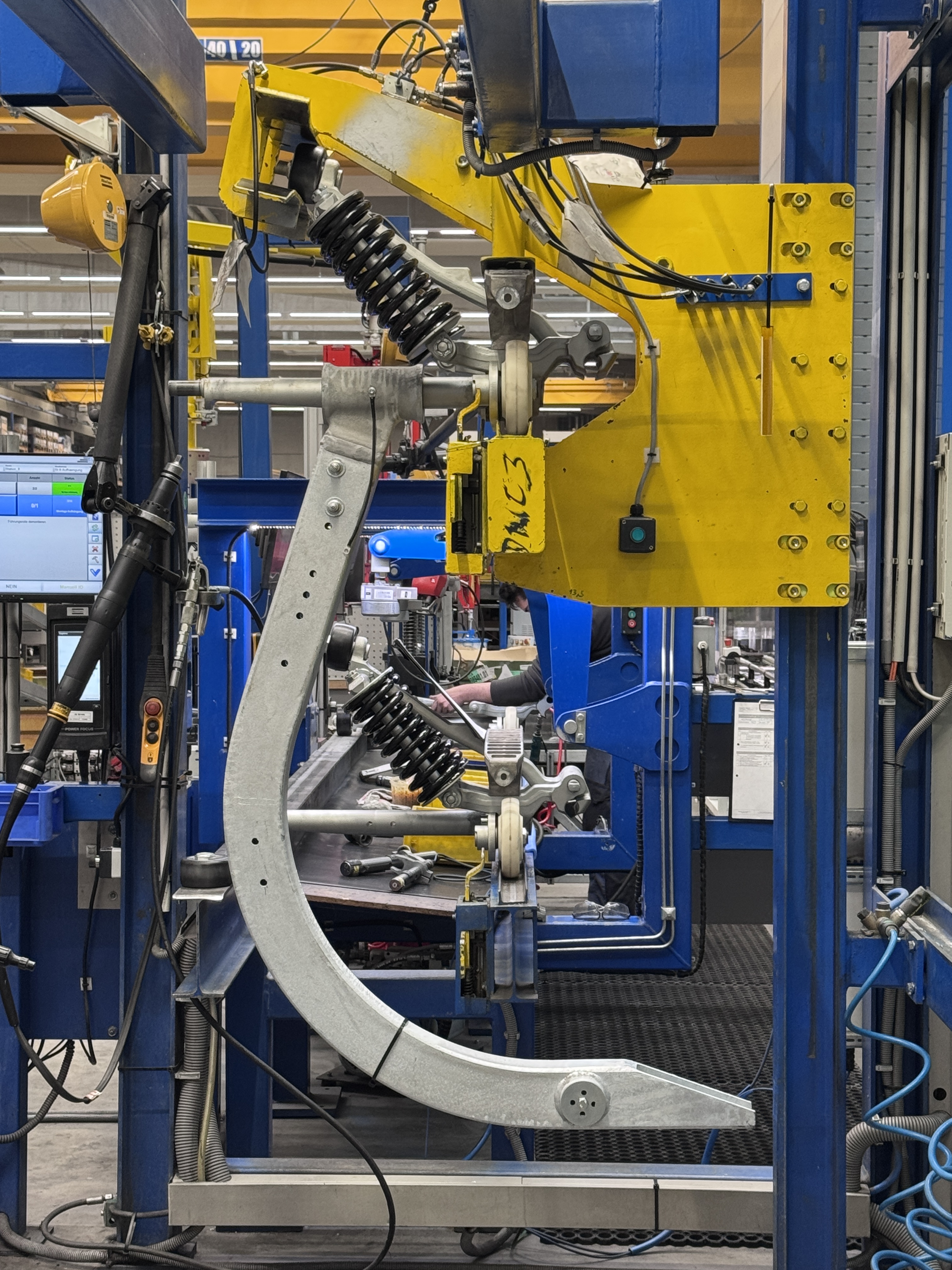

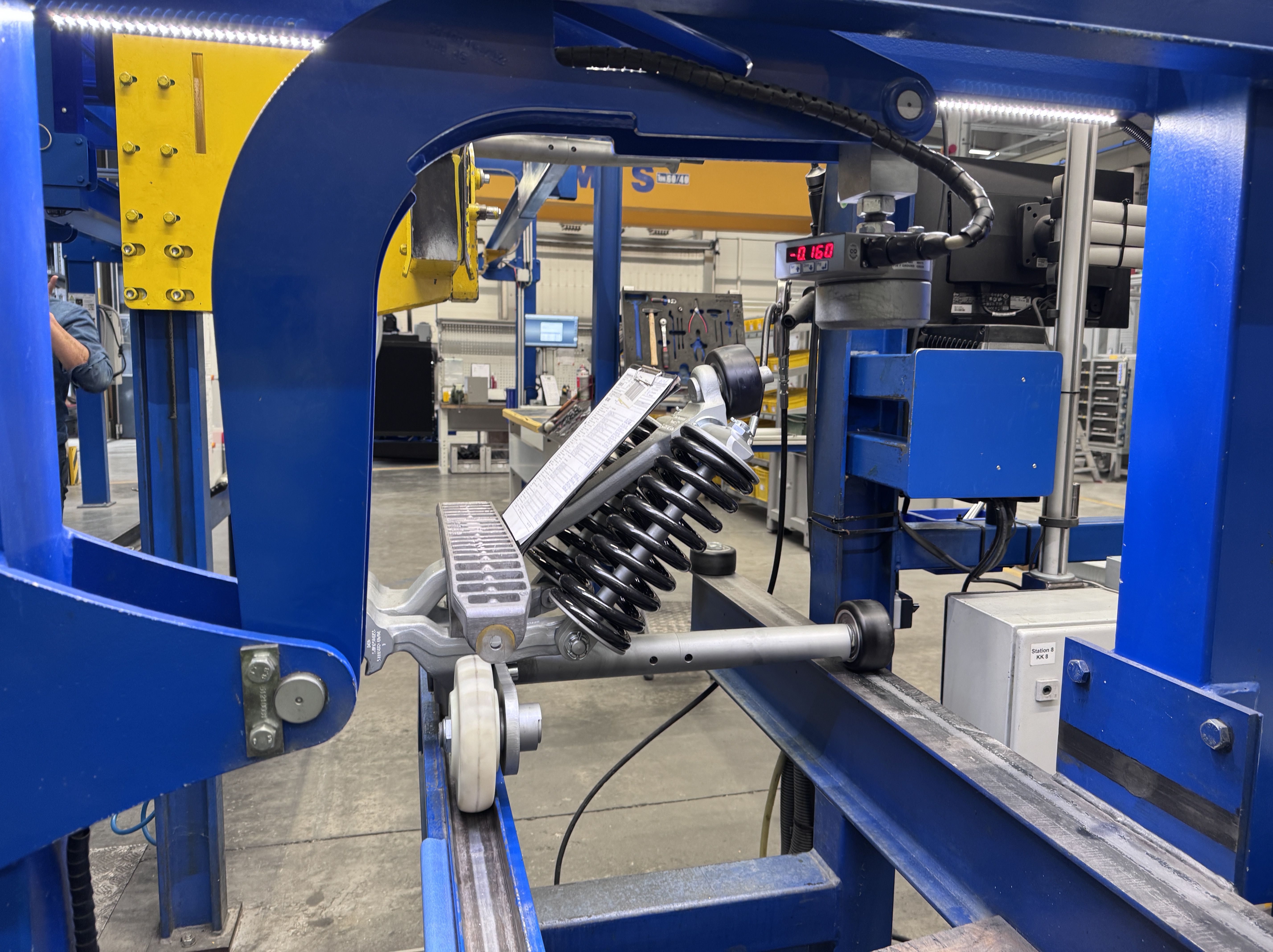

The next day we headed back to Austria and a newer factory which specializes in assembly of chairs, grips, hangers and direct drives. The 45,000 square meter Telfs plant opened in 2008 and serves just three customers: Leitner, Poma and Leitner-Poma of America. The various arms of HTI used to produce chairs and grips in different plants but consolidation to Telfs improved efficiency and quality control. In a busy year, LPOA buys 1,000 chairs from Telfs out of 2,600 to 4,000 chairs produced there. Chairs are built in batches for a specific lift. The reason for this is a six place chair, for example, can be ordered in 230 different variations depending on customer preferences. The day we were in the factory a crew was busy assembling chairs for Snowmass’ new Elk Camp six pack, set to open next season. Two Snowmass guys were on the tour and got to sit on their new chair for a photo months before first chair. Bretton Woods’ Bethlehem Express chairs had just been completed and were being readied for their boat ride to New Hampshire.

Every chair begins as a straight piece of tubular steel. An automated bending machine transforms each tube into a chair bail. Another machine cuts holes in the tube and other finishing is completed by hand. The bails are sent out for galvanization before returning for assembly. Other than the bail, the rest of a chair’s parts are sourced from a network of suppliers, many of whom also supply automakers in nearby Germany. A single chair can contain 1,500 parts and workers use high tech torque wrenches linked with software to optimize workflow. A screen shows the assembler exactly where a particular part goes on the chair.

There’s one other chair component Telfs fabricates as opposed to just assembling: bubbles! This factory will produce around 600 bubbles in 2025, all starting as flat sheets of polycarbonate. The process Leitner uses is proprietary but can be summarized as thermo stretch forming. This work is highly specialized and difficult with not every bubble meeting quality standards (around 10 percent are discarded instead of making their way to lifts.) After forming, holes are drilled and a plastic rim is glued on before the bubbles are installed on chairs.

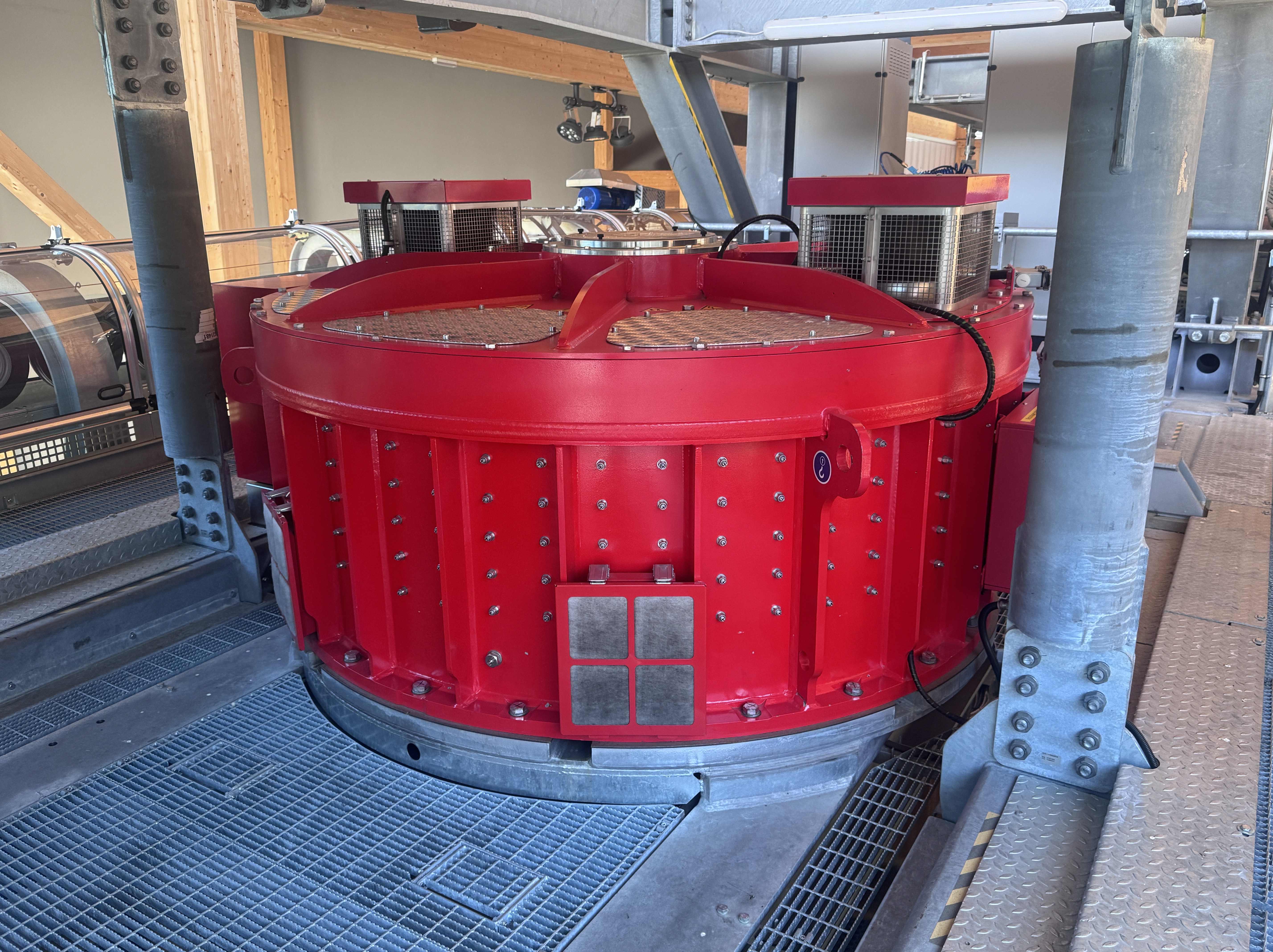

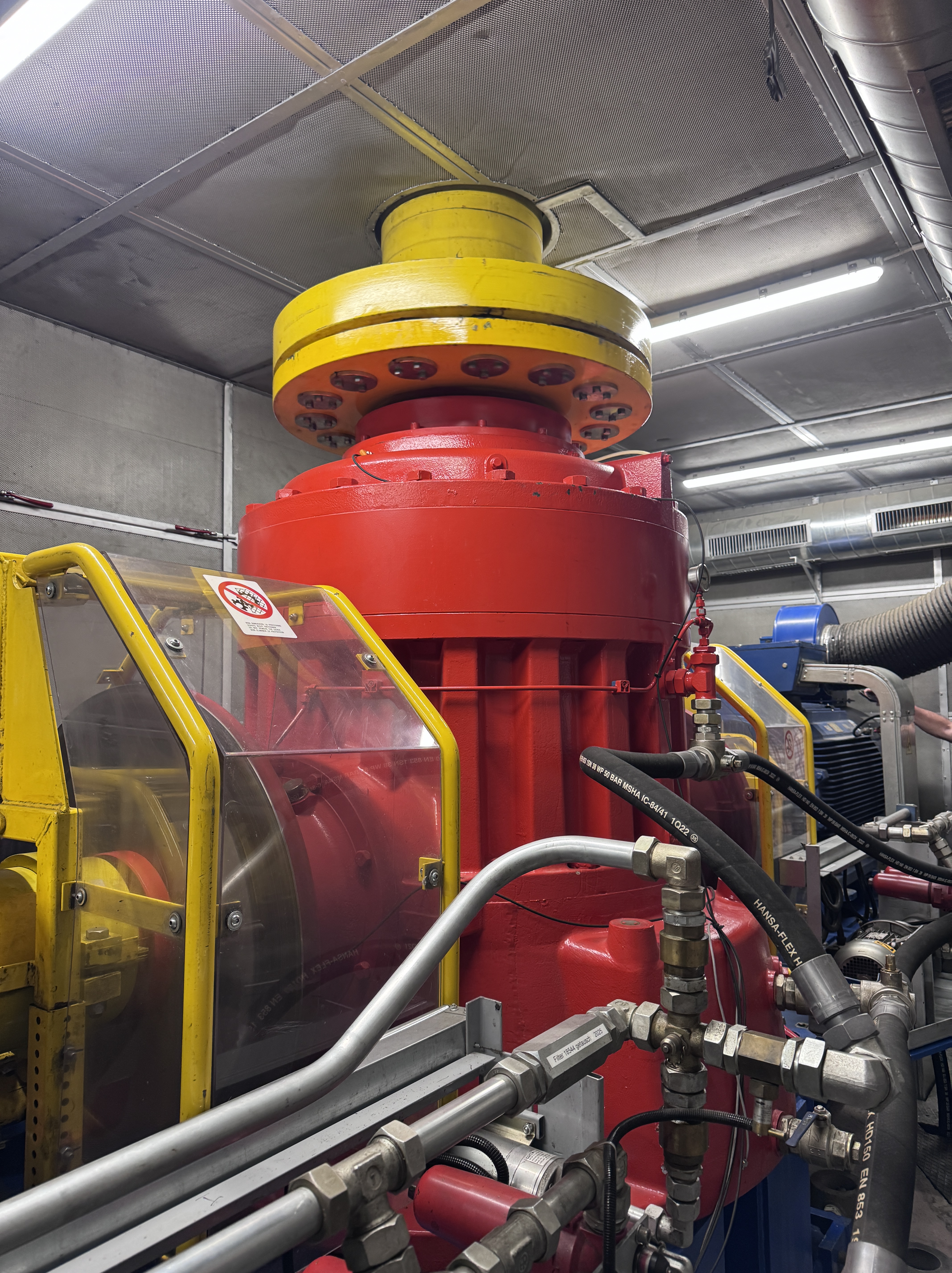

The third section of Telfs we toured was direct drive assembly. This was the first time I got to see the inside of a direct drive as normally they’re not opened once installed. Leitner was the pioneer of direct drive lifts and Telfs completes around 50 to 60 units a year, most of which stay in Europe.

The last stop was the LPA grip assembly line, designed using systems from modern automobile and aircraft factories. HTI formerly built detachable grips in three places but now every grip and hanger come off this one line. Parts are delivered to the line by an automated system but the actual assembly is done mostly by hand. Once a grip is complete, it’s tested and a series of cameras take dozens of photos to detect any anomalies. This also allows Leitner to track each grip and hanger to a specific production run on a specific date by a specific employee. The grip and hanger mechanisms are then shipped together to project sites. Once on site, crews simply connect a chair to a hanger with one bolt. This is fast but also ensures quality and safety with most of the assembly done in a controlled environment rather than a ski area parking lot.

After Telfs we ventured up to Stubai Glacier, home to a spectacular Leitner 3S and numerous other lifts. Although we weren’t skiing, several gondolas and chairlifts still carried skiers at higher elevations. Many towers were pinned to the glacier rather than traditional foundations. On the 3S, carriers can be parked at all three stations, allowing the line to be cleared of cabins automatically in a matter of minutes. Of course each section is driven by a direct drive. This lift is so big that tire sections are run by motors rather than PTO belts. These helper motors are bigger than those powering entire chairlifts in the Midwest.

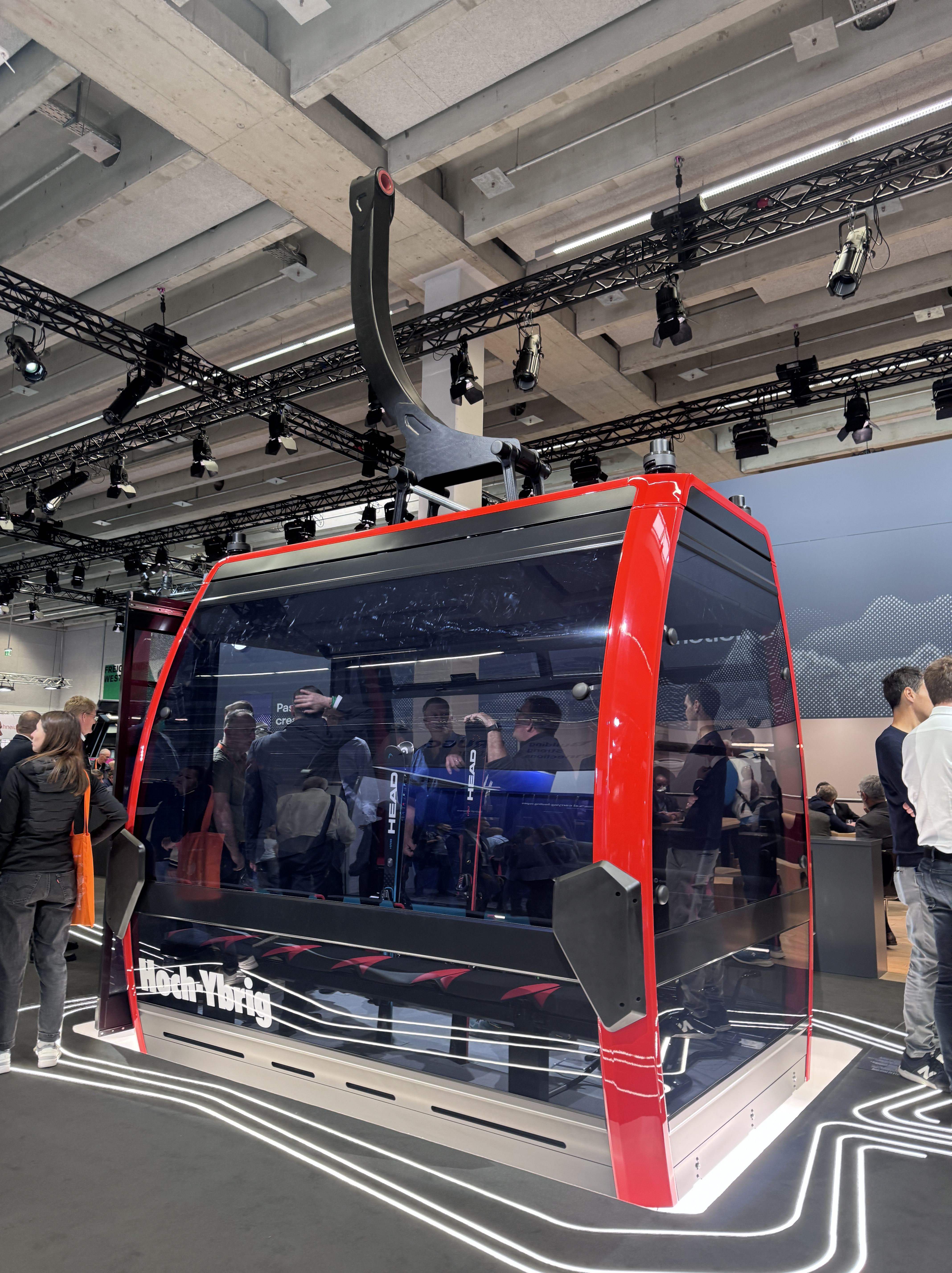

Our last stop was Innsbruck, home to the Interalpin mountain technology tradeshow. Before the show, we ventured up the Nordkette Cable Car, which Leitner part owns. This ski area is accessible right from downtown Innsbruck via a Leitner funicular railway. The funicular includes a bridge over a river, several tunnels and grades ranging from zero degrees to very steep. At the top of the funicular, we rode a series of jig back tramways to reach a 2,334 meter summit. It was foggy that day so I didn’t take many pictures of the two trams we rode.

This was my second time to Interalpin and I could spend days there. If a company sells technology to ski areas, they come to Interalpin. The Leitner booth featured a ConnX autonomous gondola cabin, several Symphony gondolas and a Leitner premium chair (the new Ropera detachable was unveiled the day after our visit.)

Doppelmayr of course had a large presence including a 3S cabin for an installation opening next winter in the Dolomites, a 10 seater cabin from Paris’ upcoming urban gondola and a Stella cabin for the soon-to-open TRI-Line at Hoch-Ybrig, Switzerland. MND was there too with a cabin from their Orizon detachable line. AI was a major focus of the show with manufacturers highlighting software products to improve maintenance and operations.

I haven’t even mentioned all the delicious food we ate, the good times had in the evenings and many other warm people we encountered. Thank you to Daren Cole, Jon Mauch and everyone at Leitner-Poma for including me on the trip. My advice to anyone interested in lifts who has not been to Europe: Go!

Sundance Resort Announces Upper Mountain Expansion

Sundance, Utah today revealed plans for its fifth new lift in ten years, the Electric Horseman Express. The mountain’s second detachable quad will run from near the bottom of Wildwood to the top of Red’s, rising an impressive 1,850 vertical feet in six minutes. The back mountain expansion will open in phases with nine new trails and 60 acres opening this winter. The new lift will debut in 26/27 along with 105 acres adjacent to Bishop’s Bowl. The nearby Flathead lift, a 1975 Thiokol, will remain for now but eventually be removed.

Doppelmayr will construct the Electric Horseman Express along a steep, 4,400 foot alignment requiring 16 towers. The lift’s eccentric name is a nod to a 1979 film starring Robert Redford, who owned Sundance for 51 years. Redford sold the mountain in 2020 to two real estate investment firms, which have pumped tens of millions into new lifts, terrain, parking, a daylodge and hotel over the past five years.

“The addition of the Electric Horseman Express will transform how our guests experience the back mountain, allowing skiers and riders to lap all of the new and existing terrain in a single high-speed lift ride,” said Czar Johnson, Chief Operating Officer. “The expanded acreage gives locals even more reason to choose Sundance Resort for their season pass, and provides our traveling guests enough variety to make our new Inn at Sundance their home base for exploration,” he continued.

News Roundup: Retrofits

- US ski resorts report their second best season ever with 61.5 million visits.

- Colorado releases a detailed report on Winter Park’s gondola tower evener beam failure last December. Leitner-Poma will retrofit or replace similar beams on existing lifts and modify the beam’s design for future installations.

- The Kicking Horse gondola hanger failure remains under investigation but the resort will replace all hangers and not operate the gondola until mid-summer at the earliest.

- Homewood to install its D-Line gondola in 2026 after years of delays.

- McCauley Mountain to sell Hall chairs from the former Big double.

- The Covid-delayed Timber expansion at Tremblant is back on the table.

- The White Mountain National Forest seeks comments on Waterville Valley’s proposed village-to-mountain gondola.

- Eaglecrest, Alaska continues to lose money with its planned gondola still in the parking lot.

- Salt Lake Community College launches a training program for lift maintenance professionals.

- Wildcat’s Snowcat triple, which missed all of last season, to get a new haul rope, drive, controls, comm line and operator houses.

- A Park City billionaire acquires the PCMR Town Lift plaza, envisions a future gondola.