- Timberline begins the NEPA process for a gondola from Government Camp to Timberline Lodge, requiring less than one acre of new permit area.

- West Virginia opens the first of two Doppelmayr gondolas in State Parks.

- A paraglider survives being caught in a moving gondola in Switzerland.

- Leitner’s apple ropeway opens in Italy.

- A funicular railway crashes in Portugal, killing 16 people, with the investigation focused on the wire rope.

- Leitner-Poma and Skytrac’s parent company invests in HKD Snowmakers; will consolidate DemacLenko and HKD in North America.

- A gondola to Disneyland is floated in Anaheim with unproven technology called Whoosh.

- The last day for Cannon Mountain’s tram will be October 26th; it’ll continue running for administrative purposes.

- Black Mountain, New Hampshire reports its highest skier visits ever but also growing pains with noise complaints from neighbors.

- The Okanagan Gondola previews the view from the top of the upcoming sightseeing lift.

- Killington’s former Sunrise lodge and base of the Northeast Passage triple are for sale.

- Homewood commences gondola construction.

- Here’s what happens to a glacier-pinned lift when the glacier recedes.

- Powder Mountain walks back its map showing DMI being installed for 2026-27.

HTI Group

An Adventure in Europe with Leitner-Poma

A few weeks ago I ventured to the Alps with a delegation from Leitner-Poma of America. LPOA is the North American arm of High Technology Industries, the holding company behind iconic European ropeway builders Leitner, Poma and Bartholet. While Leitner-Poma of America fabricates upwards of 85 percent of its equipment in Colorado and Utah, the US outpost partners closely with its sister companies back in Europe. The trip included peers from a dozen US and Canadian resorts along with Leitner-Poma employees and partners (full disclosure, LPOA covered the cost of my trip other than airfare.)

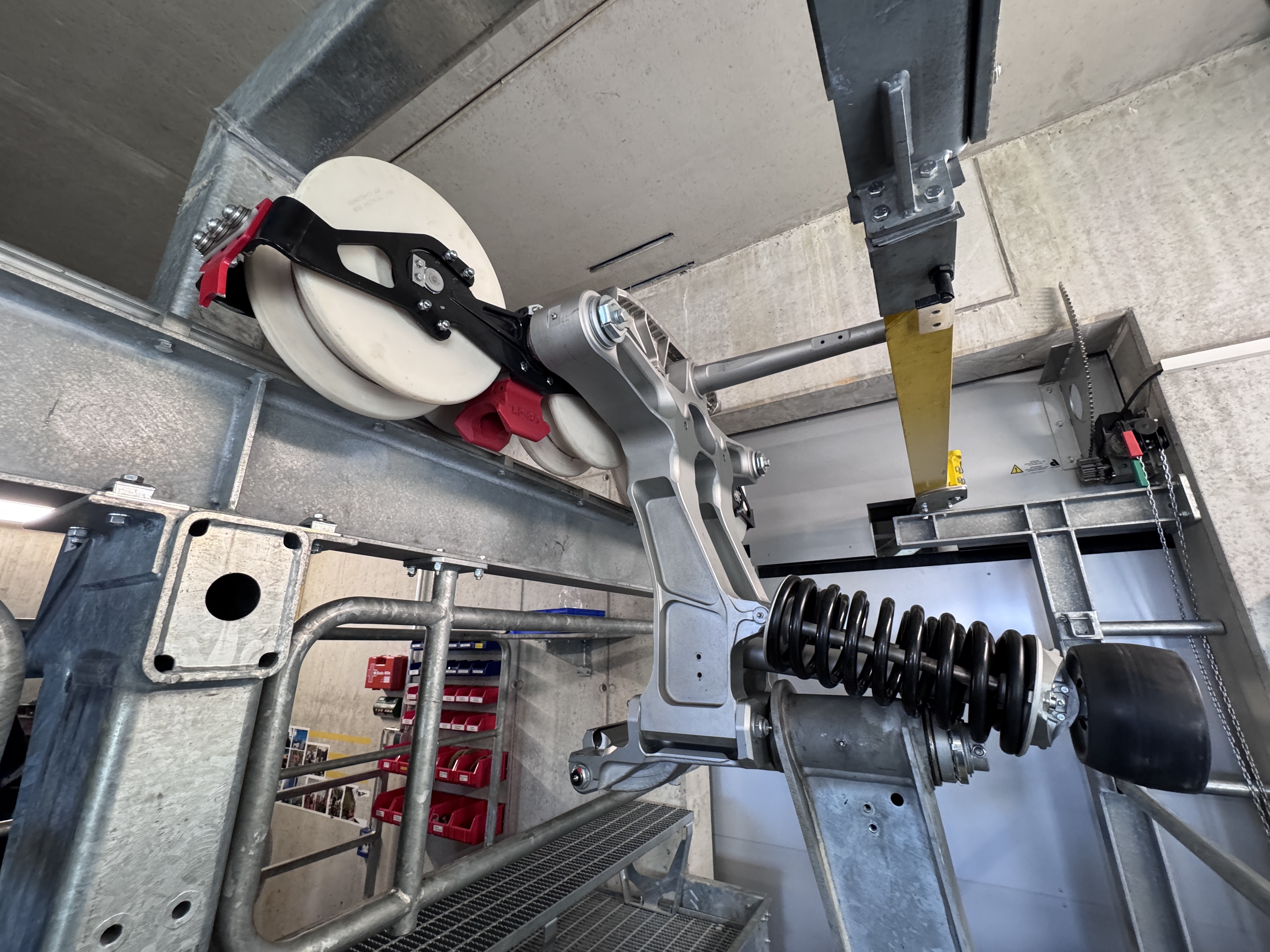

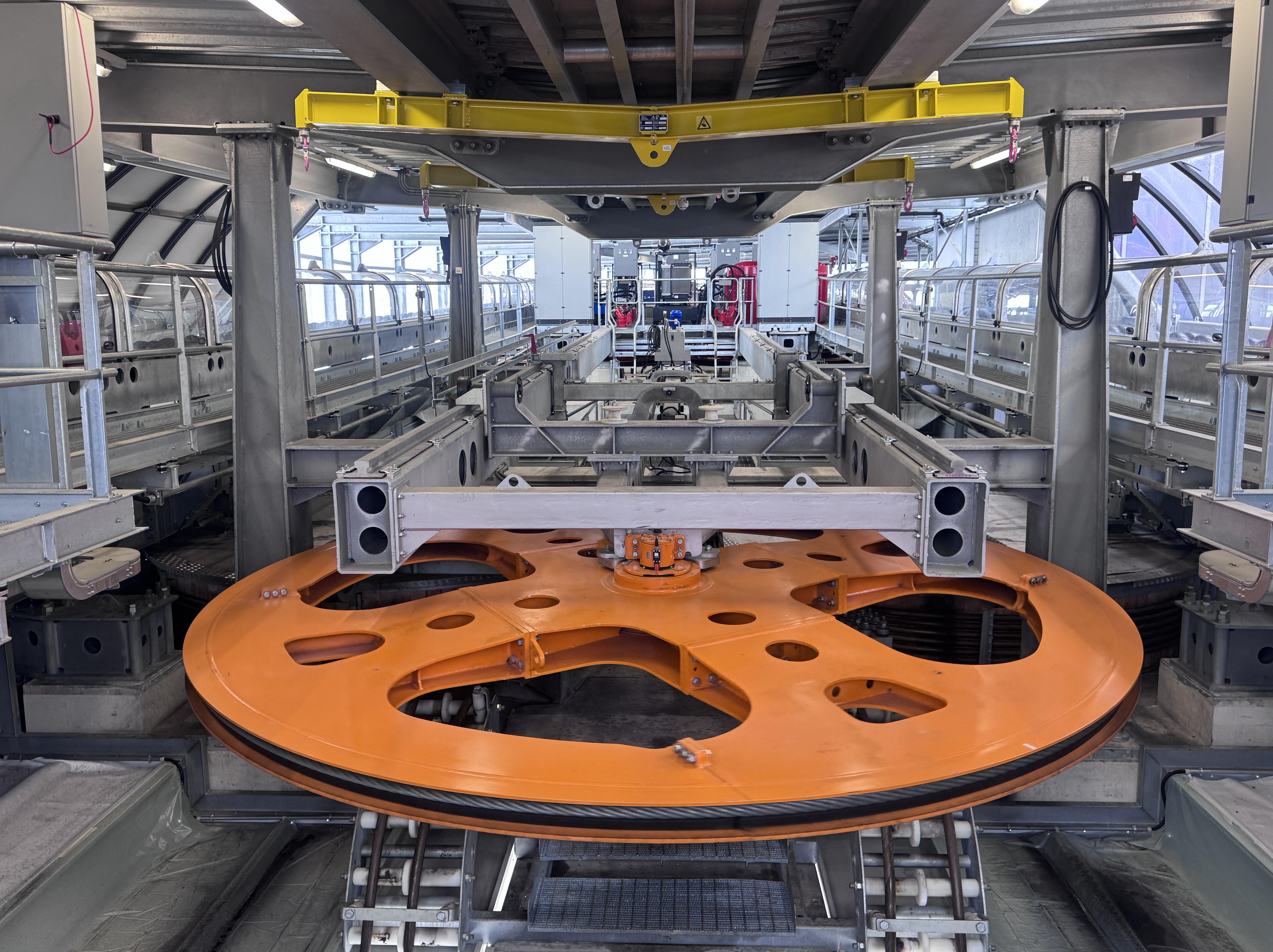

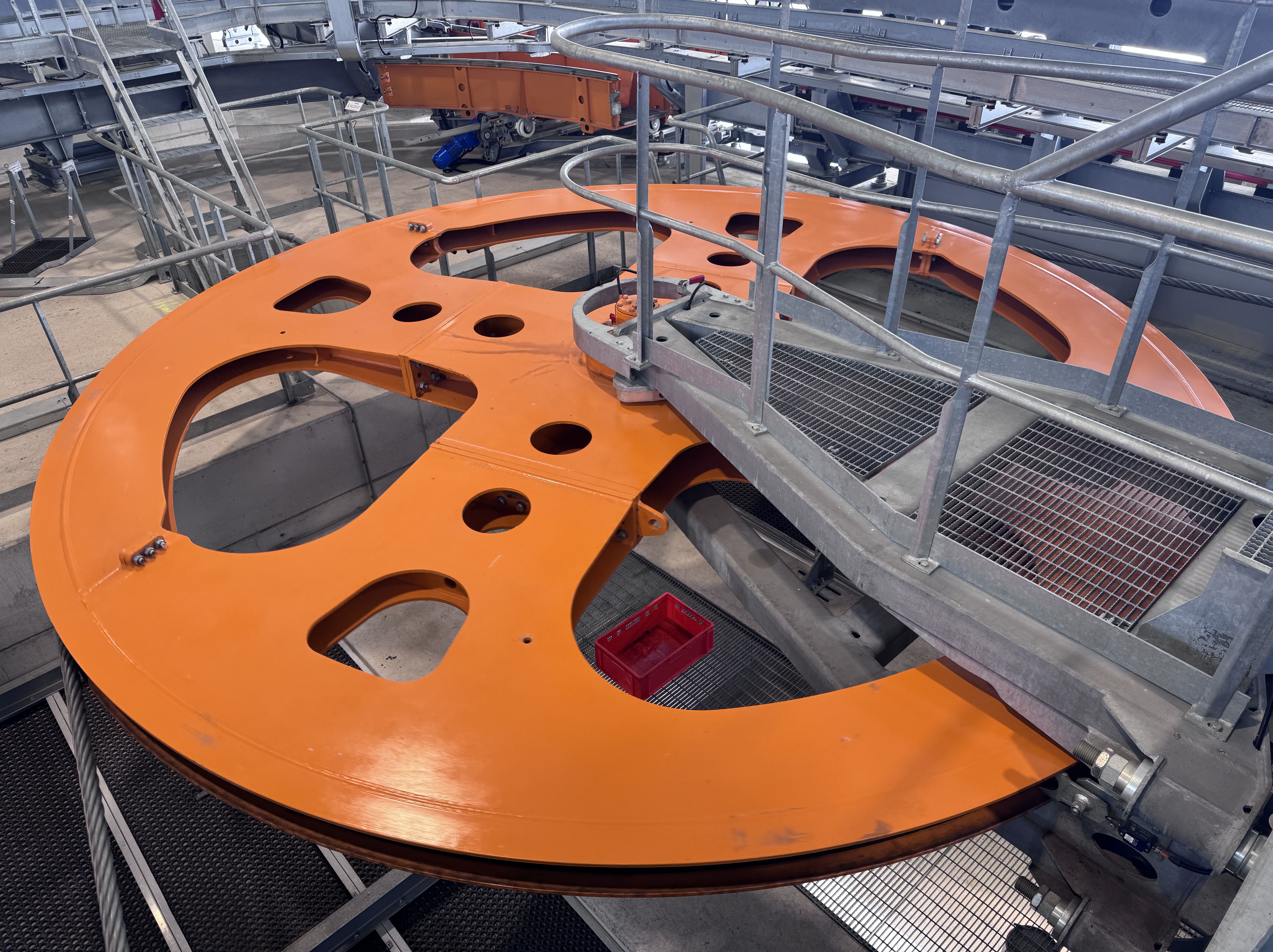

Our first stop after arriving in Munich was the Nebelhorn, near the town of Oberstdorf. Leitner constructed a state-of-the-art 2S system here in 2021, replacing several jig-back tramways. A 2S combines the efficiency of a monocable gondola with the stability and long spans of a tram. The Nebelhornbahn features two sections, automated parking and striking Symphony cabins designed by Pininfarina. Oberstdorf Lifts CEO Henrik Volpert took us on a fantastic tour of the gondola’s motor rooms, maintenance bays and parking areas. Not only does Henrik oversee seven ski areas in the region but he also serves as President of the German Ski Areas Association.

At the top of the 2S, we continued onto an older jigback tramway, the first of several on this trip. It was closing day for this resort and locals were still skiing on the upper mountain while we ate lunch.

After lunch we headed to the other side of the valley, where another of Henrik’s mountains had already opened for summer. This family ski area features a mountain coaster, several kid-friendly activities and hiking in the summer season (there’s no real offseason here.) We rode a neat monocable gondola with a 90 degree angle station to mid-mountain. Everything on the lift was top of the line including Leitner’s premium stations, a direct drive and Diamond EVO cabins.

The next day took us through Austria to Italy, where Leitner’s first 3S system operates between the city of Bolzano and the mountain village of Ritten/Renon (towns in this region carry both German and Italian names.) This unique 3S operates in a pulse fashion with cabins coming to complete stops in the stations while the line keeps moving at varying speeds. The 3S serves as public transit for more than a million riders a year and costs just five Euros to ride. The lift spans nearly 15,000 feet with ten 35 passenger cabins. At the top, an electric train carries riders further up the plateau with views of the Dolomites.

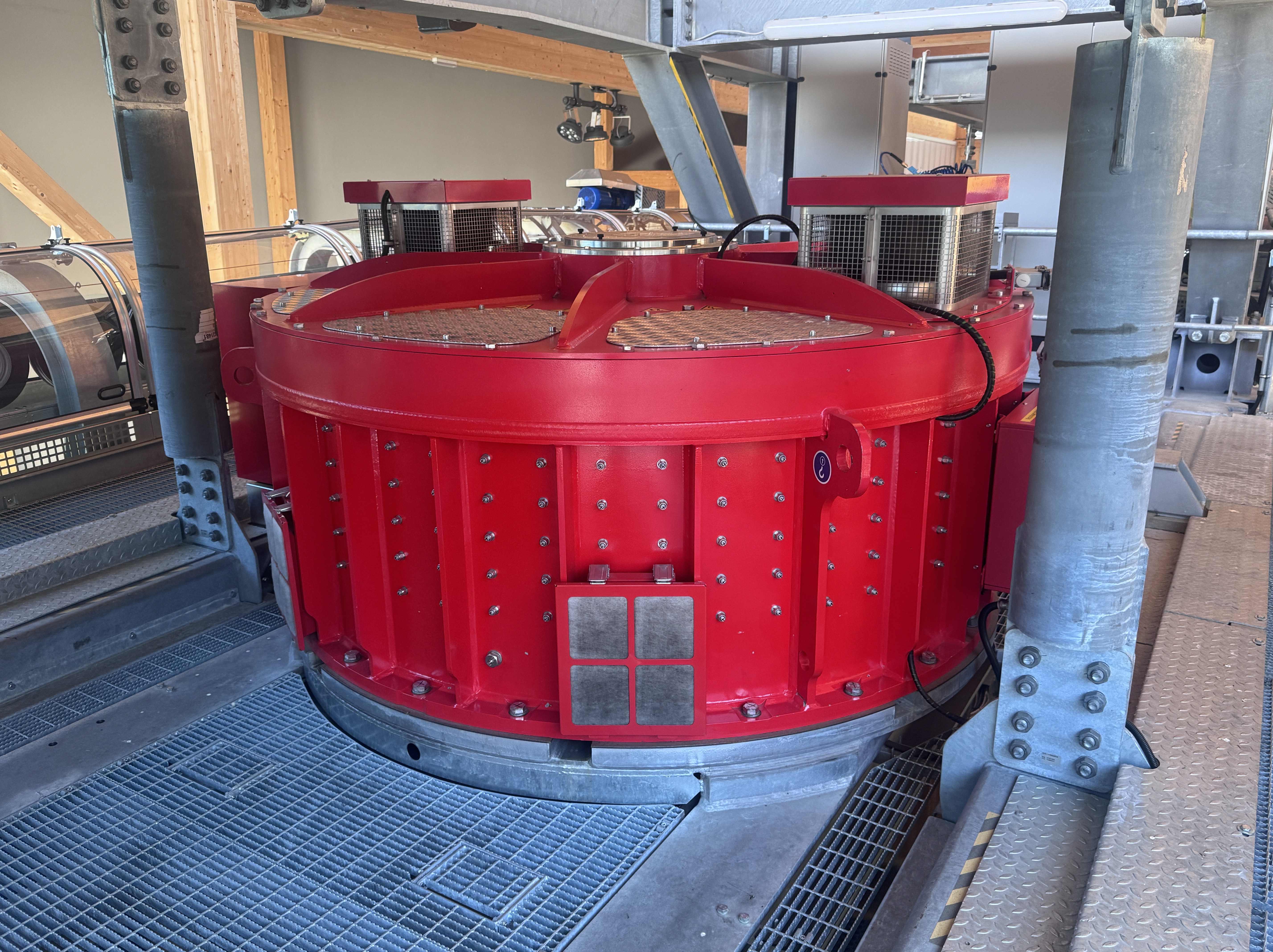

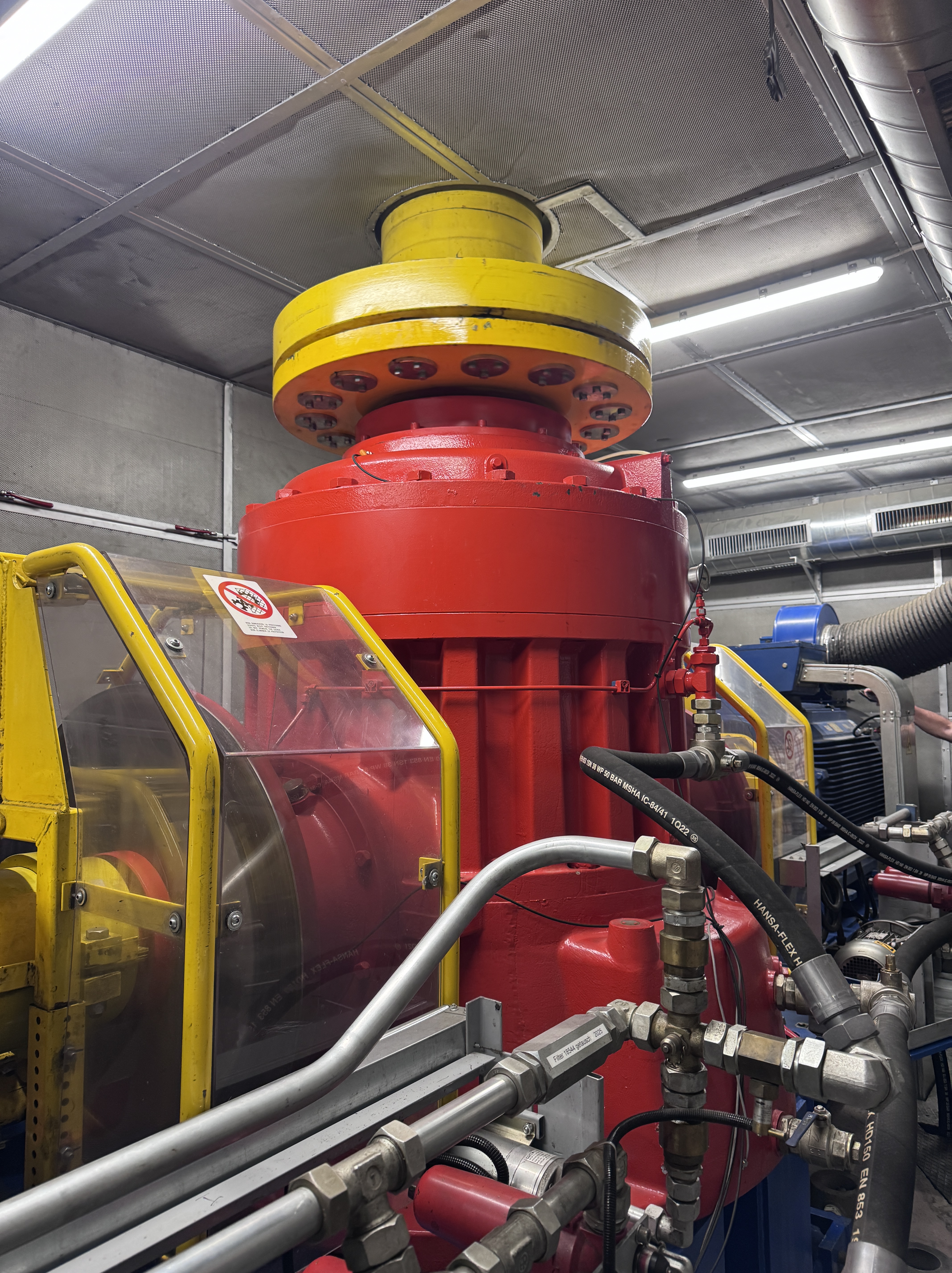

A highlight of the trip was seeing Leitner’s factories, the largest of which lies in the company’s hometown of Sterzing. There’s a ski area right in town, of course, but it had closed for the season. Our host here was Anton Seeber, the friendly leader of HTI Group and its many brands. Sterzing is a true production facility with workers and machines cutting and welding raw steel into bullwheels, tire banks and towers. Sterzing also produces casings for direct drives used all over the world. We visited this factory on a Sunday so no one was working but it was cool to see components in varying stages of completion.

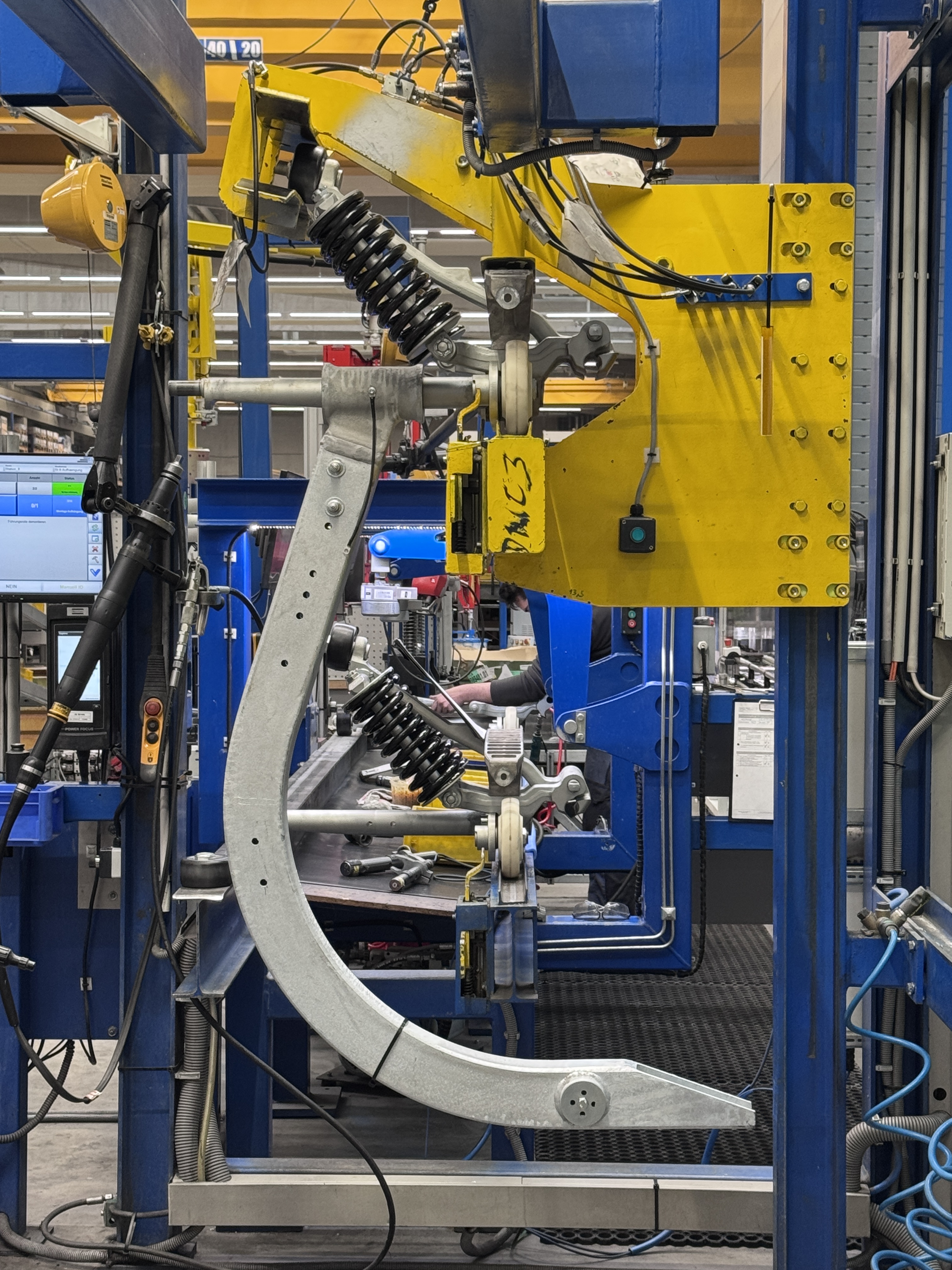

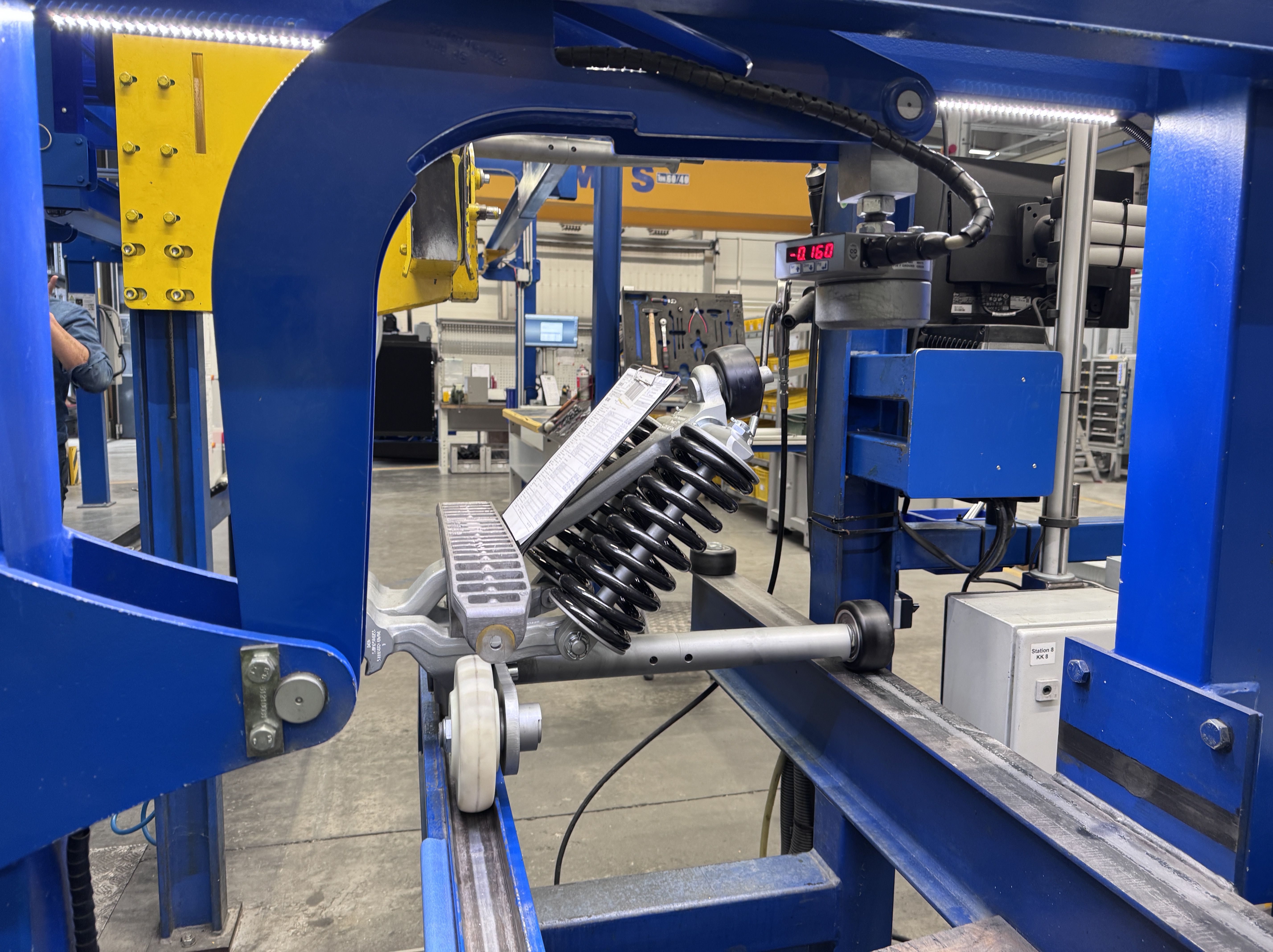

The next day we headed back to Austria and a newer factory which specializes in assembly of chairs, grips, hangers and direct drives. The 45,000 square meter Telfs plant opened in 2008 and serves just three customers: Leitner, Poma and Leitner-Poma of America. The various arms of HTI used to produce chairs and grips in different plants but consolidation to Telfs improved efficiency and quality control. In a busy year, LPOA buys 1,000 chairs from Telfs out of 2,600 to 4,000 chairs produced there. Chairs are built in batches for a specific lift. The reason for this is a six place chair, for example, can be ordered in 230 different variations depending on customer preferences. The day we were in the factory a crew was busy assembling chairs for Snowmass’ new Elk Camp six pack, set to open next season. Two Snowmass guys were on the tour and got to sit on their new chair for a photo months before first chair. Bretton Woods’ Bethlehem Express chairs had just been completed and were being readied for their boat ride to New Hampshire.

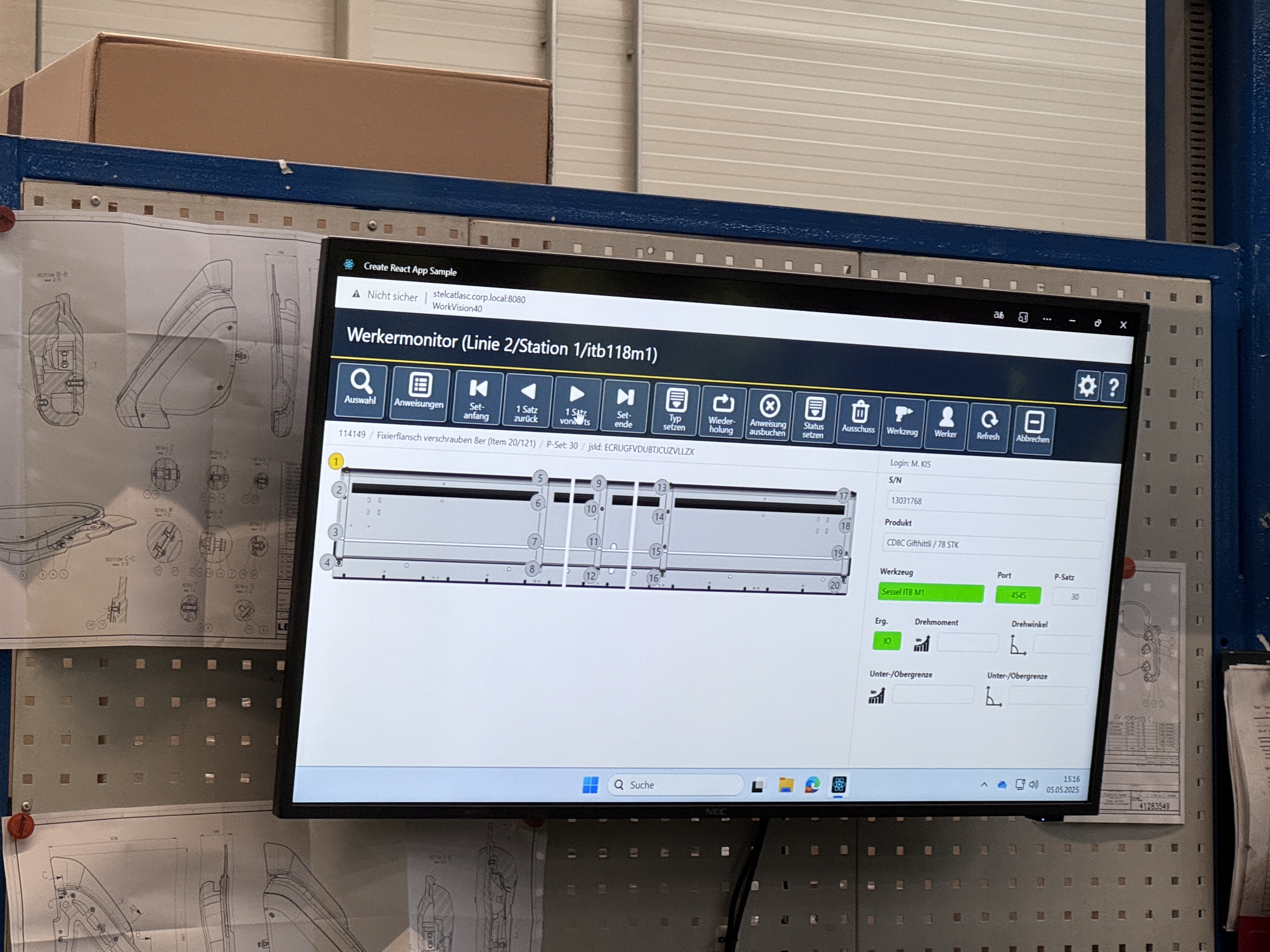

Every chair begins as a straight piece of tubular steel. An automated bending machine transforms each tube into a chair bail. Another machine cuts holes in the tube and other finishing is completed by hand. The bails are sent out for galvanization before returning for assembly. Other than the bail, the rest of a chair’s parts are sourced from a network of suppliers, many of whom also supply automakers in nearby Germany. A single chair can contain 1,500 parts and workers use high tech torque wrenches linked with software to optimize workflow. A screen shows the assembler exactly where a particular part goes on the chair.

There’s one other chair component Telfs fabricates as opposed to just assembling: bubbles! This factory will produce around 600 bubbles in 2025, all starting as flat sheets of polycarbonate. The process Leitner uses is proprietary but can be summarized as thermo stretch forming. This work is highly specialized and difficult with not every bubble meeting quality standards (around 10 percent are discarded instead of making their way to lifts.) After forming, holes are drilled and a plastic rim is glued on before the bubbles are installed on chairs.

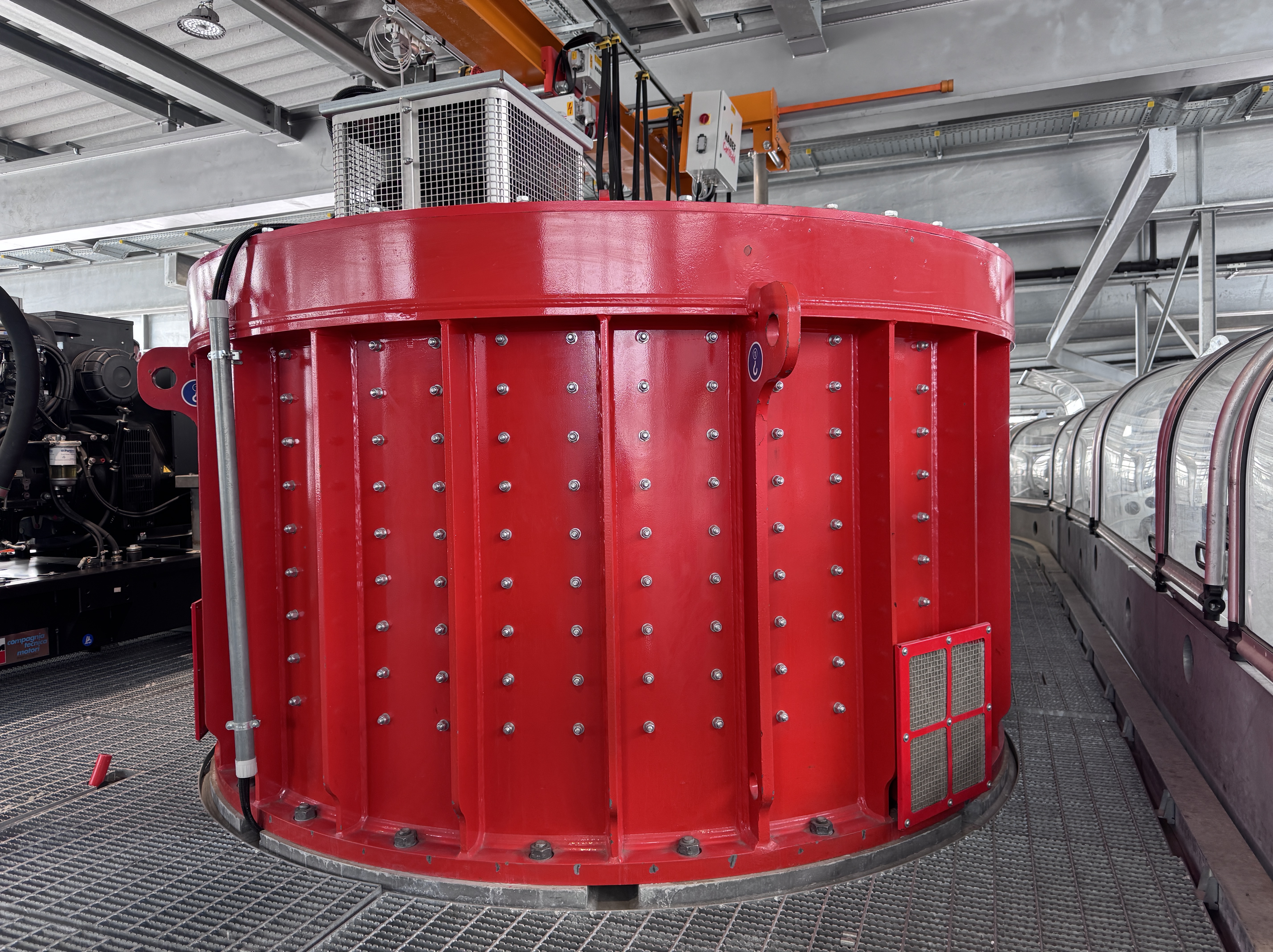

The third section of Telfs we toured was direct drive assembly. This was the first time I got to see the inside of a direct drive as normally they’re not opened once installed. Leitner was the pioneer of direct drive lifts and Telfs completes around 50 to 60 units a year, most of which stay in Europe.

The last stop was the LPA grip assembly line, designed using systems from modern automobile and aircraft factories. HTI formerly built detachable grips in three places but now every grip and hanger come off this one line. Parts are delivered to the line by an automated system but the actual assembly is done mostly by hand. Once a grip is complete, it’s tested and a series of cameras take dozens of photos to detect any anomalies. This also allows Leitner to track each grip and hanger to a specific production run on a specific date by a specific employee. The grip and hanger mechanisms are then shipped together to project sites. Once on site, crews simply connect a chair to a hanger with one bolt. This is fast but also ensures quality and safety with most of the assembly done in a controlled environment rather than a ski area parking lot.

After Telfs we ventured up to Stubai Glacier, home to a spectacular Leitner 3S and numerous other lifts. Although we weren’t skiing, several gondolas and chairlifts still carried skiers at higher elevations. Many towers were pinned to the glacier rather than traditional foundations. On the 3S, carriers can be parked at all three stations, allowing the line to be cleared of cabins automatically in a matter of minutes. Of course each section is driven by a direct drive. This lift is so big that tire sections are run by motors rather than PTO belts. These helper motors are bigger than those powering entire chairlifts in the Midwest.

Our last stop was Innsbruck, home to the Interalpin mountain technology tradeshow. Before the show, we ventured up the Nordkette Cable Car, which Leitner part owns. This ski area is accessible right from downtown Innsbruck via a Leitner funicular railway. The funicular includes a bridge over a river, several tunnels and grades ranging from zero degrees to very steep. At the top of the funicular, we rode a series of jig back tramways to reach a 2,334 meter summit. It was foggy that day so I didn’t take many pictures of the two trams we rode.

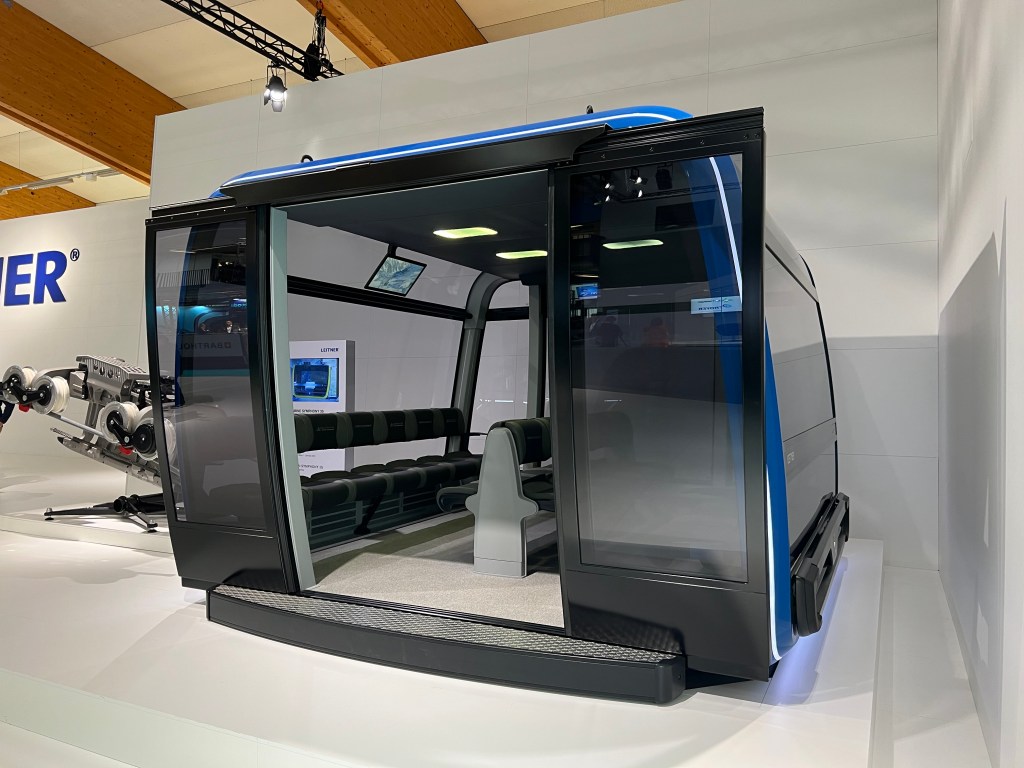

This was my second time to Interalpin and I could spend days there. If a company sells technology to ski areas, they come to Interalpin. The Leitner booth featured a ConnX autonomous gondola cabin, several Symphony gondolas and a Leitner premium chair (the new Ropera detachable was unveiled the day after our visit.)

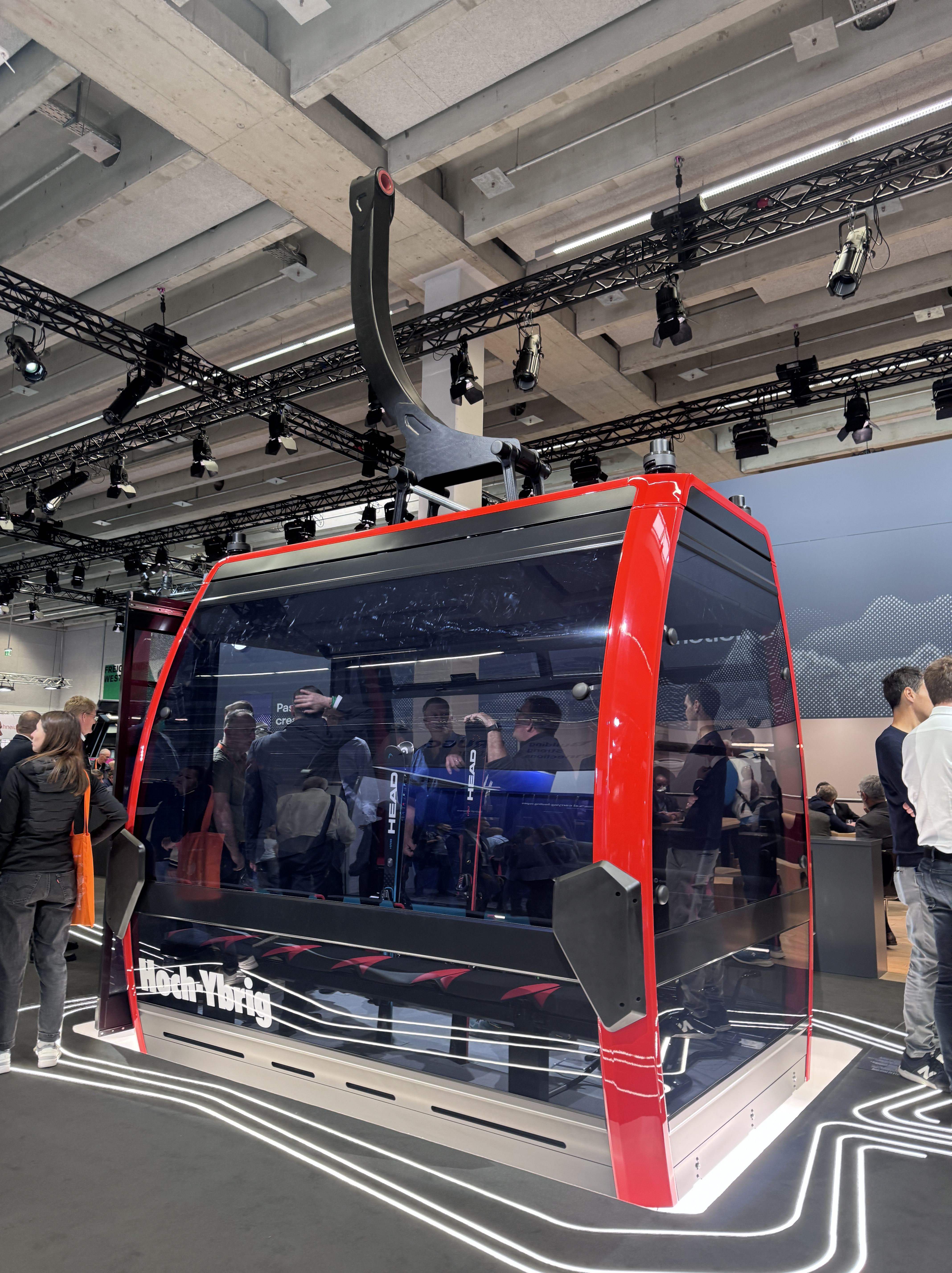

Doppelmayr of course had a large presence including a 3S cabin for an installation opening next winter in the Dolomites, a 10 seater cabin from Paris’ upcoming urban gondola and a Stella cabin for the soon-to-open TRI-Line at Hoch-Ybrig, Switzerland. MND was there too with a cabin from their Orizon detachable line. AI was a major focus of the show with manufacturers highlighting software products to improve maintenance and operations.

I haven’t even mentioned all the delicious food we ate, the good times had in the evenings and many other warm people we encountered. Thank you to Daren Cole, Jon Mauch and everyone at Leitner-Poma for including me on the trip. My advice to anyone interested in lifts who has not been to Europe: Go!

News Roundup: Pacific Northwest Icons

- HTI, the parent company of Agudio, Bartholet, Leitner, Poma, LPOA and Skytrac, reports stable revenue of €1.4 billion and record R&D investment of €41 million.

- Leitner teases “the exclusive launch of a groundbreaking new standard for monocable uni-directional ropeways” at Interalpin.

- Leitner also nears completion of a material transport gondola that includes a 1,600 foot underground tunnel.

- The next phase of the Bartholet RopeTaxi on demand gondola network is delayed to December.

- President Trump tempers announced tariffs on most countries to 10% for 90 days.

- Calls continue for the Government of Quebec to terminate its lease with Resorts of the Canadian Rockies for Mont-Sainte-Anne.

- Freakonomics tackles the economics of ski areas with help from Loveland and Mt. Ashland.

- Mt. Hood Meadows to retire the Blue double without replacement, raffle the chairs.

- Alpental plans an all weekend celebration for the retirement of iconic Chair 2.

- Doppelmayr breaks ground on its new Salt Lake City building.

- French authorities propose nearly €2 million in fines against MND and its investors for alleged disclosure and insider trading violations.

- You can buy an Overbrook chair from Ski Butternut

- McCauley is also selling chairs.

- CBS drama Fire Country to feature a ficticious ski lift disaster tonight.

News Roundup: In Memoriam

- U.S. skier visits totaled 60.4 million this season, down from last year but fifth highest ever.

- The Colorado Supreme Court rules a liability waiver doesn’t protect Crested Butte from a chairlift fall claim.

- Huff Hills, North Dakota may pack up and move to a new location.

- Leitner-Poma parent company HTI reports a 13 percent revenue increase with strong sales in North America.

- Alterra-owned Schweitzer postpones the next phase of the Schweitzer Creek Village expansion.

- Castle Mountain plans to reinstall a 1988 detachable from Sunshine Village as soon as next summer.

- The municipality of Park City approves Deer Valley’s proposed Lift 7.

- Park City Mountain to begin construction shortly on the new Sunrise Gondola.

- A Maine developer will try again to revive Big Moose Mountain.

- A proposed lift-served bike park in Conifer, Colorado moves toward public hearings.

Bartholet Ends Detachable Partnership with MND

After five years of working together, Bartholet of Switzerland and MND Group of France have terminated their joint venture partnership effective December 13th. Under the agreement, MND Ropeways utilized Bartholet’s detachable lift technology in select markets such as France and the United States while continuing to offer its own surface lifts and fixed grip chairlifts. One final MND-Bartholet detachable project under construction in France will be completed as planned.

The end of MND’s deal with Bartholet comes as little surprise. HTI Group, the conglomerate behind Leitner Ropeways and Poma, purchased a majority stake in Bartholet in March of 2022. Bartholet and MND only completed one project jointly in the United States, the Tecumseh Express at Waterville Valley, New Hampshire in 2022. That project was contracted before HTI bought Bartholet and MND hasn’t sold a chairlift in the United States since. Bartholet continues to operate as a subsidiary of HTI in Europe with a product line distinct from Leitner and Poma.

Going forward, MND Ropeways will need to find another partner or utilize its own technology in order to continue offering detachable lifts. Prior to the Bartholet deal, MND built one detachable chairlift in La Plagne, France, which opened in March 2017 but has suffered periodic technical problems. It is rumored MND may outline its future detachable plans at the Mountain Planet trade show this spring.

Manufacturers Introduce Innovations at Interalpin

If the last week and a half was quiet on the blog, it’s because I was skiing my way around Austria, Germany and Switzerland with a few lift factory visits along the way. The last stop on my journey was Interalpin, the world’s largest trade show for mountain technology which takes place in Innsbruck every two years. Thanks to Covid, this was the first Interalpin in four years with an estimated 35,000 people attending.

Doppelmayr

Doppelmayr made a splash the first day with the introduction of a new logo, the company’s first brand refresh in decades. For the first time Doppelmayr Group companies like CWA, Carvatech, Garaventa, Gassner and Frey all have logos matching the parent company’s identity. The new brand will be introduced to international subsidiaries over time.

Doppelmayr’s sprawling two story booth featured numerous cabins, chairs, grips and carriages from an 8 seat Carvatech gondola all the way up to a 32 passenger CWA Atria.

A 20 passenger cabin called Stella debuted for the first time. This cabin will be available for both Tri-Line 3S and 20 passenger monocable gondolas. Stella fills the gap between the ubiquitous Omega and much larger Atria model, which has only been used to two lifts to date. Future 20 passenger monocable gondolas will utilize a new D9000 carriage, which is built around two side by side D5000 grips.

Introduced last year, Tri-Line is a streamlined version of the 3S gondola with smaller stations requiring less concrete. The first Tri-Line is under development at Hoch-Ybrig, Switzerland. Both Tri-Line and 20-MGD are based off standard D-Line stations and can achieve up to 8,000 passengers per hour with Stella cabins that fit closely together and can open on two sides. On the three rope Tri-Line, Stella cabins will be capable of spanning longer distances between towers than monocable gondolas with high wind stability.

Doppelmayr also showcased a simplified surface lift product family called S-Line.

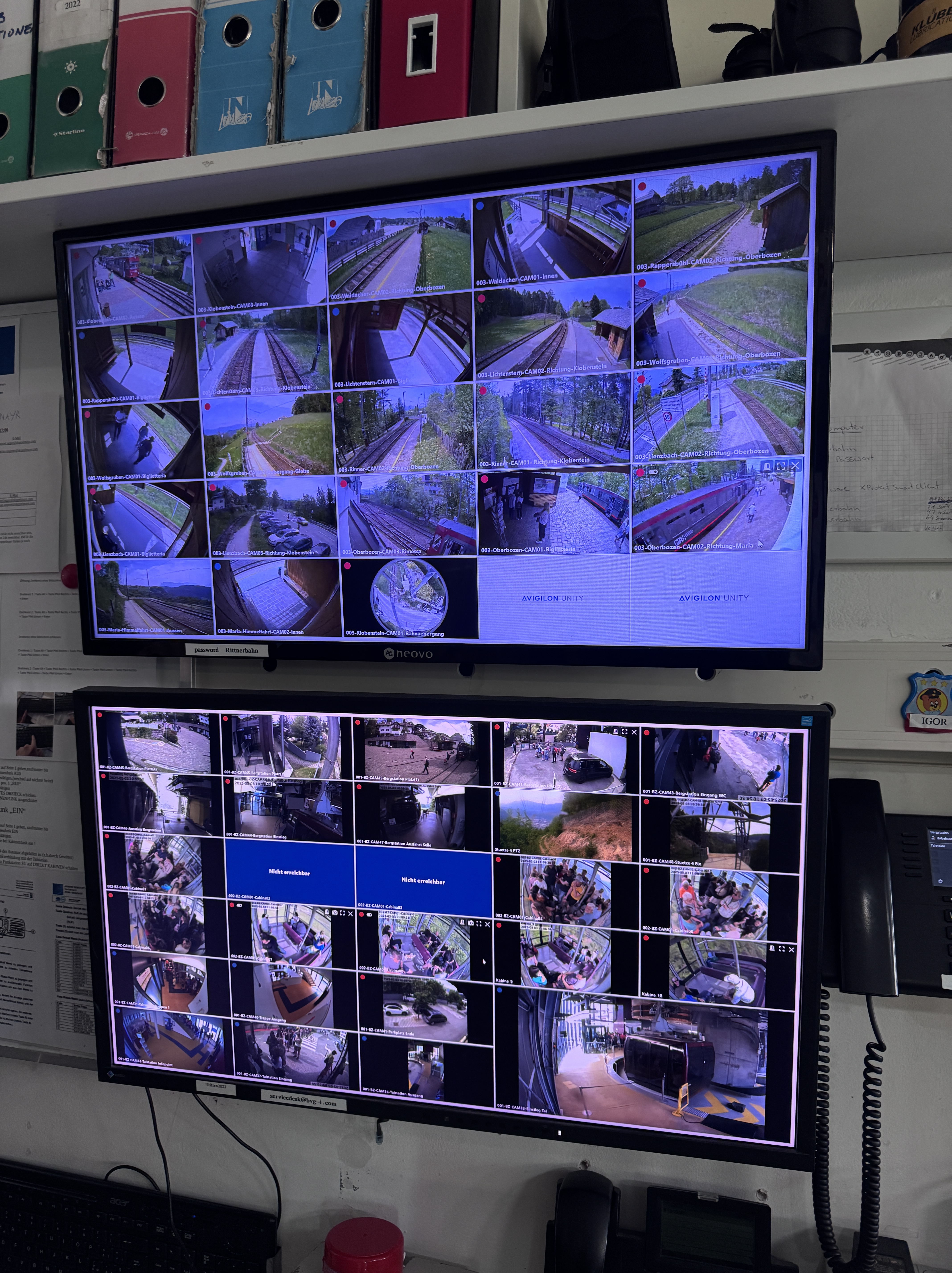

Doppelmayr had a full size mockup of an Auro autonomous gondola station which can be monitored remotely from a ropeway operations center. A chairlift version is also undergoing testing on two lifts in the region using artificial intelligence to monitor unloading. In both cases, large detachable lifts could be operated by just one person.

Also on the software front, Doppelmayr’s resort management software clair now integrates with other mountain technology providers such as Fatzer, Skidata and TechnoAlpin.

HTI Group

HTI group hosted another large booth shared between Prinoth, Leitner, Poma and DemacLenko. For the first time Bartholet was also part of the HTI area. With three different lift brands now under one umbrella, HTI showed off multiple Diamond cabins, a premium chair, Symphony gondolas and Bartholet chairs/cabins.

I got to experience both Leitner’s 2S and 3S gondolas in the surrounding mountains and was very impressed with their smooth ride and quality. The newest 2S design utilizes plastic carriage rollers and can span long distances between towers more economically than a 3S.

Bikes were a big focus with both chair and gondola loading solutions on display. The European industry has embraced vertical racks so passengers can ride on the same chairs as bikes without having to skip chairs with trays.

HTI is also getting into the software game with a resort management program called Skadii including digital logbooks to manage documentation.

Energy efficiency is a huge focus in Europe and HTI also showed off its Ecodrive program, which uses cameras to analyze lift queues and automatically adjust lift speed to save energy.

MND

MND Ropeways had a Waterville Valley style six place chair along with a gondola cabin on display. The company continues to push the benefits of providing lifts, snowmaking, avalanche control systems and summer attractions all from one supplier.

News Roundup: Sold Out

- Mexico City and Leitner inaugurate a new urban gondola line with 283 cabins and 7 stations.

- Leitner-Poma looks to hire a Sales Manager specifically for urban ropeways in North America.

- Leitner, Poma and Bartholet parent company HTI reports a record €1.3 billion in revenue for fiscal 2022.

- A skier dies after falling through a gondola cabin window in France.

- With its gondola back in operation, Mont-Sainte-Anne eyes a $100 million renewal with bids already received for two lift replacement projects.

- Doppelmayr revitalizes a 110 year old cable car over Niagara Falls.

- The Indy Pass suspends sales due to capacity limitations at partner resorts.

- Eagle Point teases multiple lift upgrades including a new connector chair.

- Powdr sells Lee Canyon to Mountain Capital Partners.

- Taos confirms Leitner-Poma will build new chairlifts on both sides the mountain this summer.

News Roundup: Back in Action

- Mt. Shasta unveils a new map showing the expansion onto Gray Butte.

- HTI Group celebrates 80 new ropeways installed this winter across its Leitner, Poma, Bartholet and Skytrac brands.

- Completion of the Lenawee Express at Arapahoe Basin is now expected in mid-December.

- Indy Pass adds Peek’n Peak, New York and Tussey Mountain, Pennsylvania.

- Doppelmayr shares energy saving operational tips with customers in Europe.

- Waterville Valley and MND postpone the load test of Tecumseh Express by a week due to delayed electrical components.

- Loon Mountain expects to open the delayed Seven Brothers some time in December.

- Sunday River plans a December 17th grand opening for Jordan 8.

- The operator of the Goldbelt Tram may invest $10 million in Eaglecrest’s pulse gondola project.

- Sterling Vineyards previews the first Omega V cabins coming to California.

- Kimberley spins the Northstar Express for the first time in nearly a year, hopes to open by the third week in December.

- The Village of Taos Ski Valley declines to sell a parcel needed for a base to base gondola, wants an easement instead.

News Roundup: Best Ever

- The Bud Light Seltzer SkyView gondola at Hard Rock Stadium becomes the Heineken High Line for the Miami Grand Prix.

- A chairlift which rotates between two fairs in California and one in Arizona now also goes to Texas.

- Granite Gorge is scheduled to be sold at a foreclosure auction next month.

- A Swiss paper interviews Roland Bartholet about his company being acquired by HTI. The brand will remain separate from Leitner and Poma, will focus on new products and help the group compete with Doppelmayr Garaventa.

- Indy Pass signs six more resorts as affiliate partners; redemptions totaled 125,000 this season.

- Gore Mountain signs with Leitner-Poma for the North Creek Ski Bowl detachable.

- Doppelmayr proposes a $200 million urban gondola system in Auckland, New Zealand.

- Bottineau Winter Park fundraises for a new T-Bar.

- Friends of the Tulsa Skyride say the only lift in Oklahoma may be removed in the next few weeks.

- The United States sets an all-time skier visit record – 61 million – with 11 more ski areas operating than last season.

- NSAA says offseason capital improvements will also set a record this year at $728 million.

- A big urban 3S opens in France.

- Doppelmayr’s latest Bike Clip carriers will make their North American debut at Loon Mountain.

- Mt. Rose’s first high speed quad will be called the

Tahoe Express. Update: Lakeview Express - A tram breakdown makes the news in Palm Springs.

Bartholet Joins the HTI Group

The Italian-based giant which owns Leitner, Poma, Skytrac, Sigma, Prinoth and Demaclenko has added yet another ropeway brand to its stable. High Technology Industries (HTI) announced it acquired a majority stake in Bartholet Maschinenbau AG, a Swiss manufacturer of fixed grip and detachable ropeways. The controlling share was previously held by Chinese private equity firm Cedarlake Capital. The agreement once again shifts the global ropeway landscape, which has seen relentless consolidation in recent decades. Chairman and CEO Roland Bartholet and the Bartholet management team will remain in place and the brand will continue to be based in Flums, Switzerland. The company’s founding family will retain a minority stake.

It was just two years ago Bartholet partnered with a different European conglomerate, Mountain and Snow Development Group (MND) of France. MND began to develop its own detachable technology in the mid 2010s and debuted a prototype lift in 2017. That project experienced challenges and MND pivoted to utilizing Bartholet detachable designs from 2020.

MND’s ropeway division and Bartholet are set to debut their first North American detachable lift at Waterville Valley later this year. Much of that six place bubble chair has already been delivered stateside and some foundations are already complete. The Bartholet-HTI press release did not address the future of the MND partnership, though history suggests it will likely wind down. MND did not immediately respond to a request for comment.

The now larger HTI Group remains privately held while MND trades publicly on the Euronext Growth exchange under the symbol ALMND.